Contact Details

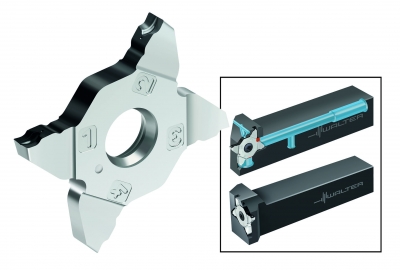

The Walter Cut MX grooving inserts deliver high levels of flatness and surface quality with their tangentially-mounted arrangement in the G3011/G3021 holders. Four cutting edges per insert multiply user productivity and, if one cutting edge breaks, the other cutting edges remain usable.

These MX grooving inserts, with widths from 0.031-0.127 in. (0.80 -3.25mm) and cutting depth of 0.24 in (6 mm), feature self-aligning tangential clamping. This self-aligning clamping feature between MX inserts and G3011/G3021 holders permits fast and user-friendly replacement of cutting edges with optimum accuracy during changeover. Also, the inserts cannot be engaged incorrectly into the holders.

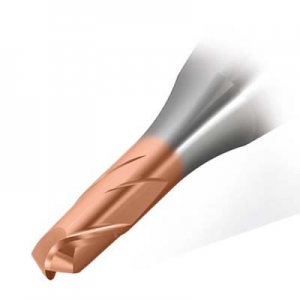

Tool life is substantially improved because of the Tiger·tec Silver PVD carbide grades. The carbide exhibits excellent toughness and allows a reduction in machining time through its optimized microstructure. Also, with Tiger·tec Silver PVD grades there is greatly reduced wear because of the integrity of the coating that is not susceptible to thermal stress variations during wet and dry machining.

The productivity of Walter Cut MX grooving inserts is enhanced by the Walter Cut G3011/G3021 toolholders, which provide longer tool life and higher productivity with precision cooling on the rake face. Additionally, the dowel pin location feature of these holders insures correct insert seating and enhanced indexing accuracy.

Related Glossary Terms

- grooving

grooving

Machining grooves and shallow channels. Example: grooving ball-bearing raceways. Typically performed by tools that are capable of light cuts at high feed rates. Imparts high-quality finish.

- microstructure

microstructure

Structure of a metal as revealed by microscopic examination of the etched surface of a polished specimen.

- physical vapor deposition ( PVD)

physical vapor deposition ( PVD)

Tool-coating process performed at low temperature (500° C), compared to chemical vapor deposition (1,000° C). Employs electric field to generate necessary heat for depositing coating on a tool’s surface. See CVD, chemical vapor deposition.

- rake

rake

Angle of inclination between the face of the cutting tool and the workpiece. If the face of the tool lies in a plane through the axis of the workpiece, the tool is said to have a neutral, or zero, rake. If the inclination of the tool face makes the cutting edge more acute than when the rake angle is zero, the rake is positive. If the inclination of the tool face makes the cutting edge less acute or more blunt than when the rake angle is zero, the rake is negative.

PRODUCTS

PRODUCTS