Cutting metal for laying ink

Cutting metal for laying ink

Reduce cycle times and time spent loading and unloading parts into a machine. Use clamps to create custom fixture plates and gang more parts per machining cycle.

END USER: AMR Machines LLC, (860) 336-6208.

CHALLENGE: Reduce cycle times and time spent loading and unloading parts into a machine.

SOLUTION: Use clamps to create custom fixture plates and gang more parts per machining cycle.

SOLUTION PROVIDER: Mitee-Bite Products LLC, (800) 543-3580, www.miteebite.com.

Be it a depiction of a micrometer, a dragon or Larry, Moe and Curly, a sizeable portion of the population likes to adorn their epidermis with tattoos. Handcrafted tattoo machines for laying the ink can be fabricated from clock radio and headphone parts, but people tend to favor professional tattoo machines rather than looking like they received their designs while doing hard time.

Austin Riley understands the trade and, in 2012, founded AMR Machines LLC, Putnam, Conn., to machine parts for tattoo machines and make and distribute the machines and their components.

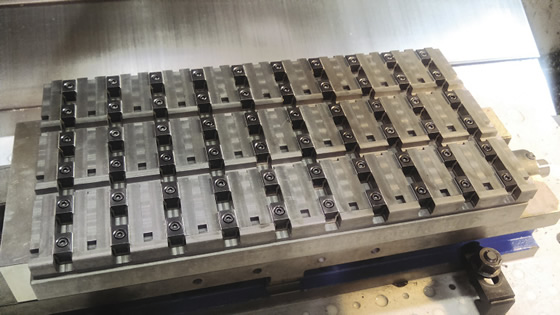

Mitee-Bite clamps enable AMR Machines to gang up to 60 parts in a fixture.

Along with another machinist, he produces the machine frames and parts on two vertical machining centers and a CNC lathe without live tooling. The workpiece materials include ductile iron, steel, brass, aluminum and Delrin. Initially, the shop was machining up to four parts at a time on a double vice, but needed a more cost-effective method. "They are low-dollar parts," he said.

Riley explained that by creating a custom fixture to gang up to 60 parts per machining cycle, he'd be able to reduce the cycle time while allowing a machine to run longer before swapping parts. Instead of constantly monitoring a machine, having a machine spindle spend more time cutting would allow Riley and his employee to perform other functions during machining, such as deburring with knives. "I do use a tumbler and media blast parts, but I have to manually remove some of the bigger burrs," he said.

Riley searched online for a solution and, after reading a forum about clamps from Mitee-Bite Products LLC, Center Ossipee, N.H., he visited the company's Web site and saw that some of its clamps fit his application. They include the Uniforce and Pitbull clamps, as well as TalonGrip vise jaws. "I make my own jaws for them," he said about the TalonGrips, "but I order the grips and the stops."

Riley noted the clamps struck him as expensive at first, but he soon realized they pull their weight in productivity. "They pay for themselves quickly." He estimated that the clamps helped boost productivity 40 to 50 percent.

In addition, because the TalonGrip system enables clamping on as little as 0.060" (1.5mm) of material, AMR Machines orders 3"×3" (76.2mm × 76.2mm) blocks of material that are 1" (25.4mm) thick to reduce costs. "Before the TalonGrips," Riley said, "I had to order blocks 1¼" thick so I had something to grab onto, and that was the next size up."

The shop still uses the double vise with the jaws on the outside to hold the 18" (457.2mm) fixture plate, or shop-made pallet, but is able to produce the parts with significantly less operator intervention. "Doing them the old way, I would've dedicated a worker to that machine for the whole day indefinitely, standing there and waiting every 3 minutes to take the parts out, flip them and hit the start button again," Riley said.

With the custom fixtures and Mitee-Bite clamps, the shop produces about 2,000 parts every few months. Although a fixture plate gets unloaded and reloaded between machining cycles, Riley noted AMR Machines could implement a system to unload/load one plate of parts while another is being machined if volume increases.