Drilling with pinpoint precision

Drilling with pinpoint precision

Achieve tightened tolerances and increase throughput when machining microholes and other microscale features. Two new machine tools, each with 0.5µm positioning accuracy and a 50,000-rpm maximum spindle speed.

END USER: Vermont Microdrilling, (800) 698-2308, www.vermontmicrodrilling.com.

CHALLENGE: Achieve tightened tolerances and increase throughput when machining microholes and other microscale features.

SOLUTION: Two new machine tools, each with 0.5µm positioning accuracy and a 50,000-rpm maximum spindle speed.

SOLUTION PROVIDER: Kern Precision Inc., (508) 943-7203, www.kernprecision.com.

Connecting the dots takes on a whole new meaning at Vermont Microdrilling. Actually, the dots are holes as small as 38µm (0.0015 ") in diameter, up to 10 diameters deep and with a pitch, or center-to-center hole distance, of 51µm (0.0020 "). Parts can require 12,000 or more holes and take up to 48 hours to complete.

The Barnet, Vt., company specializes in microdrilling probe cards but has machined parts that also might require milling, contouring and other operations for a host of projects, including the Airborne Laser for the U.S. Air Force, the Hubble telescope and high-speed photography equipment at Los Alamos National Laboratory. As Vermont Microdrilling tackles new projects, its range of workpiece materials continues to grow. The list includes brass, copper, stainless steel, Inconel, titanium, polycarbonates, ceramics, polyimide and plastics, such as Vespel and Polyether Ether Ketone (PEEK).

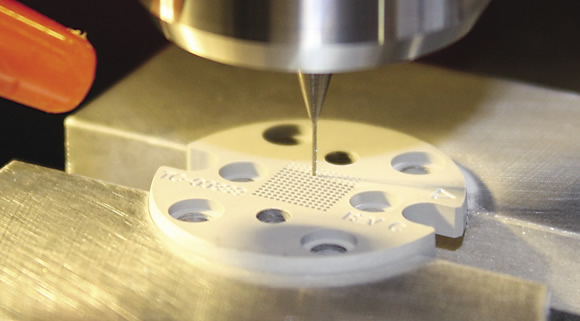

Vermont Microdrilling utilizes a Kern 25 micromachining center for drilling tight-tolerance holes.

However, as hole sizes began to get even smaller and tolerances tighter as a result, General Manager Mark Cote noted a couple of the company's machine tools from the mid to late 1980s with maximum spindle speeds of 10,000 rpm couldn't rotate the tiny drills fast enough to effectively and efficiently produce the holes. The shop was struggling to hold tolerance requirements. In addition, as those machines started to wear, parts and electronics became hard to find—and expensive—because of limited supply.

"Mainly the electronics were getting tired, and they were not easily replaceable anymore," Cote said. "Sometimes we had to repair an existing board rather than just replacing it because we couldn't get it anymore. Repairing an electronic problem could cost more than the machine was worth."

The time had come to research the machine tool market and develop a wish list of features a new machine would have. After examining machine tools from various builders, visiting some and having sample parts drilled, Vermont Microdrilling decided Kern Precision Inc., Webster, Mass., offered what it needed. The company first purchased a Kern 25 and later a Kern HSPC. Both micromachining centers have a 50,000-rpm maximum spindle speed and 0.5µm positioning accuracy. "For speed and accuracy, these machines are best suited for what we're doing," Cote said, adding that throughput increased dramatically.

In addition, the Kern machines use HSK 25 toolholders instead of the previous equipment's BT 40 holders, which were significantly larger than the HSK 25s and not balanced for high spindle speeds, Cote pointed out. "The runout limits are much tighter on the new machines because of the toolholders."

The new machines also have significantly larger-capacity toolchangers than the machines they replaced. For example, the HSPC holds up to 90 tools, which is beneficial for some parts with long run times.

Vermont Microdrilling uses a Kern micromachining center to drill a 0.32mm-dia. (0.0126 ") hole configuration into a part for a vertical probe card.

According to Cote, Vermont Microdrilling faces formidable accuracy specifications, in the nanometer range for some applications. The Kern machines maintain tight tolerances in diameter, position, angle and surface quality, and produce holes with high aspect ratios. In addition, the machine tools extend tool life by minimizing vibration.

The new machines have the ability to robotically load and unload parts, but part volumes at Vermont Microdrilling are not high enough yet to require that capability. However, the ergonomic design of the machines enhances manual loading and unloading, according to Cote.

Vermont Microdrilling customized the Kern machines with a laser tool measurement system, touch probes for measuring parts and 100× video cameras to view cutting tools during machining and help track tool wear. "We're looking at chip evacuation, if the tool is breaking or happens to break, and any misalignment with the tool for the feature we're machining," Cote said.

Having the right machine tools for the job certainly is important, but is not the only critical element at Vermont Microdrilling. "Experience is the key here," Cote said. "There is a lot of art mixed with science to produce these microdrilled patterns and components. Our machinists have from 8 to 20 years of on-the-job training in dealing with a variety of projects, materials, speeds and feeds, accuracy specs and more. This diversity sharpens their skills, keeps us looking for insights and prepares us for the next job."