New developments promise change for turning

New developments promise change for turning

Long-staid turning technology is suddenly hot thanks to several recent advancements.n

There's a perception in some quarters that turning hasn't changed much in the past century. But people who think that are not up on current metal-cutting events. Makers of turning tools and equipment lately have been unveiling significant developments. These manufacturers say turning personnel who embrace the advances can reap many benefits, including shorter cycle times, finer surface finishes, improved chip control, longer tool life and fewer tool changes.

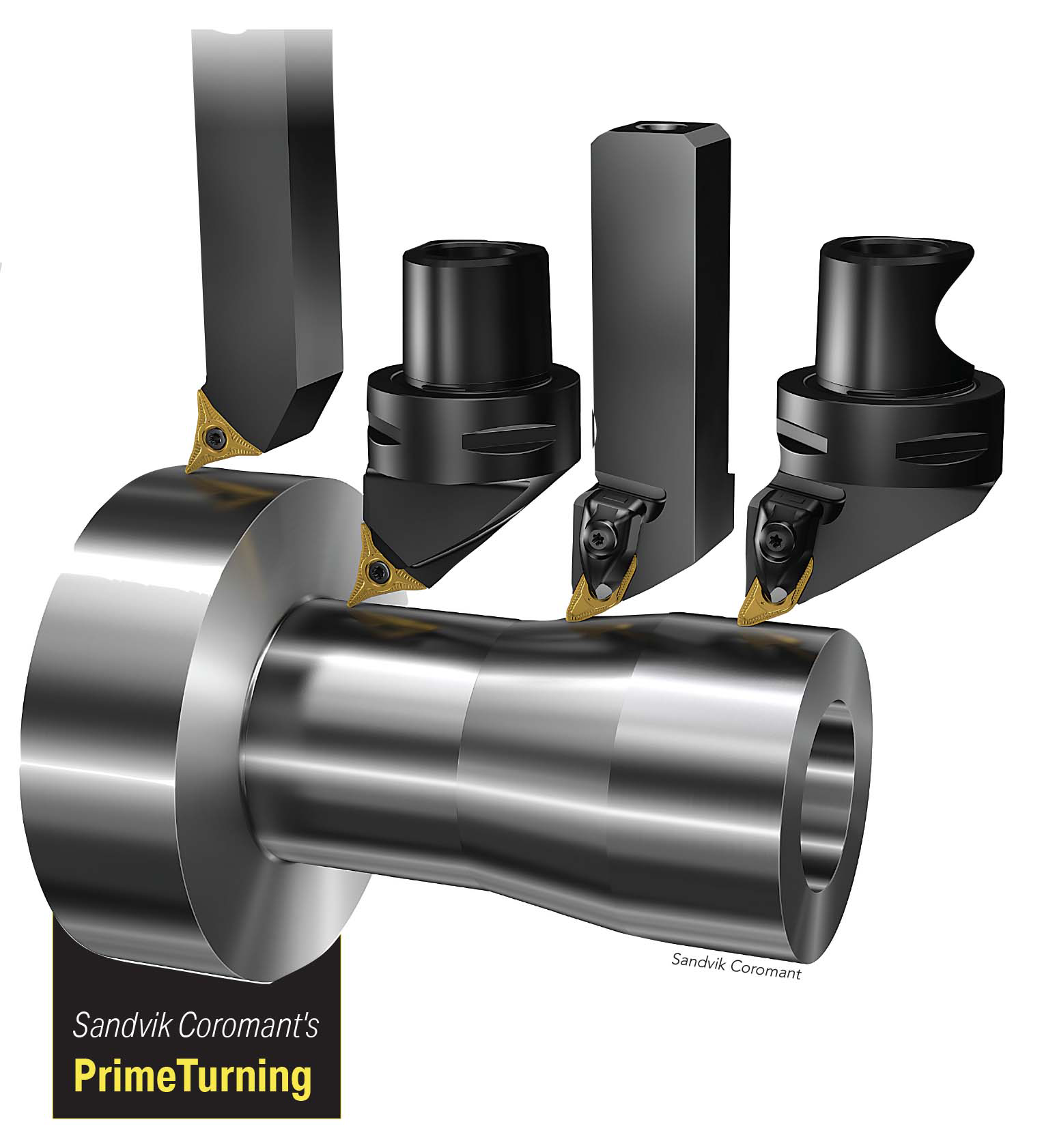

It could be said that one of these developments takes turning in a new direction. With conventional turning, feeding is done toward the chuck in the z-axis. But with PrimeTurning from Sandvik Coromant Co., Fair Lawn, New Jersey, multidirectional turning is possible with one tool. PrimeTurning users even can feed a tool back and forth while it stays in the cut. The result is faster machining, especially when roughing while taking multiple passes.

Sandvik Coromant's CoroTurn Prime inserts are key to PrimeTurning. They come in two designs: A-type for light roughing, finishing and profiling and B-type for roughing. When machining with both designs, a small lead angle relative to the feed direction is supposed to speed up the cutting process and improve surface quality.

Consider the Advantages

Sandvik Coromant reports that the combination of the PrimeTurning method and CoroTurn Prime tools can increase productivity by 50% or more compared with conventional turning. In addition, the entire cutting edge of CoroTurn Prime inserts can be used.

"They allow you to put wear all the way around the edge of the insert so you can get better tool life," said John Winter, Eastern U.S. product manager.

Since the inserts are suitable for a number of operations, they also reduce tool changes. Another advantage is their impact on chip control.

"A lot of people will say back turning with a tool isn't new, but you have never been able to get chip control when doing that," Winter said. "So we have designed (insert) geometries that give us chip control in both directions."

New chipbreaker, toolholder and coolant delivery designs also are aimed at improving chip control. Thanks to all these developments, he said, PrimeTurning users are effectively controlling chips when machining low-carbon steel, which presents a major challenge for conventional turning. He cited an application in which a customer employed PrimeTurning for better chip control when machining low-carbon steel and furthermore experienced 300% improvement in tool life and 25% reduced cycle time.

"I've seen 200% cycle time improvements" in other PrimeTurning applications, Winter said, "but sometimes the gains may be more on the tool life side than on the productivity side."

On the downside, existing turning programs no longer work for shops that switch to multidirectional turning. Sandvik Coromant offers a code generator to help users create the programs needed for PrimeTurning and produces ISO code that users can cut and paste into current programs. In addition, he said, Sandvik Coromant machining specialists help new PrimeTurning users develop the best programs for their parts.

The company also provides online help for shops trying to determine whether PrimeTurning suits their applications. Well-supported parts generally are good candidates, Winter said, pointing out that the process can exert a lot of tool pressure on a part.

"So if it's not supported well," he said, "you can get deflection and vibration."

Another consideration is that PrimeTurning typically benefits large-volume manufacturers more than those with small part runs. Winter stressed, however, that the process can substantially improve low-volume machining too.

"High volume is definitely the place where you can see the biggest gains," he said. "But we've also had onesie twosie (applications) running Inconel and were able to make gains there. It depends

on the commitment of the customer."

Turning on a Roll

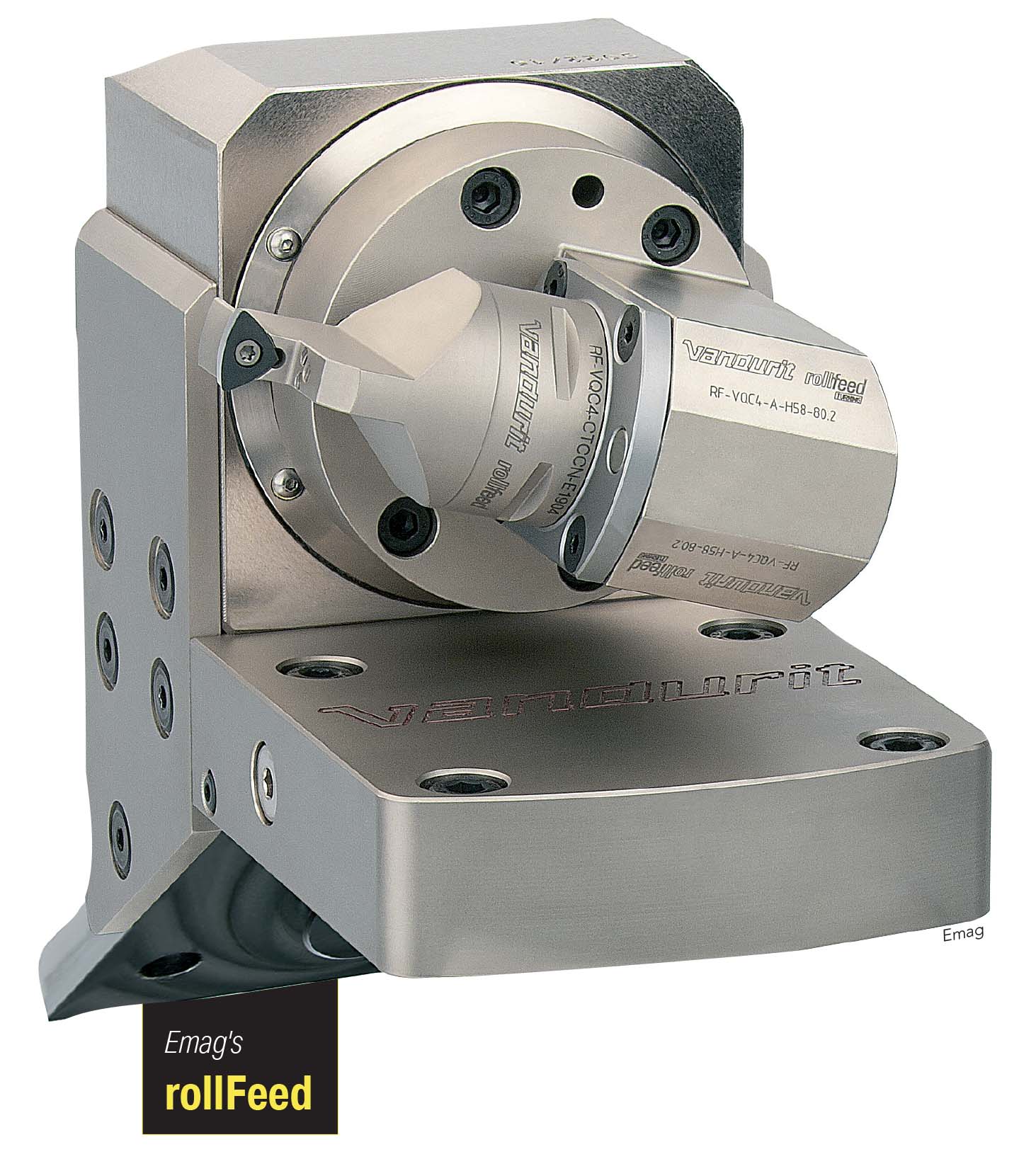

Another recent advance that can boost turning productivity is rollFeed turning, jointly developed by cutting tool manufacturer Vandurit GmbH, Leverkusen, Germany, and machine tool builder Emag GmbH & Co. KG, Salach, Germany. (Subsidiary Emag LLC is in Farmington Hills, Michigan.) The patent pending process is available on Emag's vertical turning machines and suitable for any horizontal turning machine, said Philipp Ruckwied, manager of cutting technology. With rollFeed turning, a specially shaped insert swivels on a b-axis while moving on the x- and z-axes.

"Normally, you turn with x and z," he said. "But with this b-axis movement, you can roll the curved cutting edge so that the contact point is moving along the edge."

Since the contact point moves during machining, each point along the cutting edge heats up for only a few seconds, Ruckwied said, adding that the entire cutting edge is used during the process. These two factors combine to significantly reduce insert wear. For hard turning operations that use rollFeed, he said tool life can be up to five times longer than with conventional hard turning.

The rollFeed process requires a special unit for b-axis movement, as well as a special tool body and special inserts. Because the method involves an additional axis, the process also requires special programming. Emag worked with CAD/CAM software developer Open Mind Technologies AG, Wessling, Germany, to create software for rollFeed based on Open Mind Technologies' hyperMill CAM product.

Featuring an unusually large cutting-edge radius for turning, the rollFeed process — with its swiveling insert — is designed to improve surface finishes. For applications that don't require high surface quality, though, the big cutting-edge radius allows the system to run faster, Ruckwied said. He noted that shops that switch to rollFeed turning can get finer surface finishes with the same feed rate they used before or the same surface quality with a feed rate three to five times higher than before.

A Different Angle

Like PrimeTurning and rollFeed, a third development puts more movement into the turning process. With conventional turning, a tool with a fixed approach, or lead, angle is applied to create a workpiece contour. However, Mamer, Luxembourg-based Ceratizit SA introduced a tool system that offers 360 degrees of freedom in the angle at which the insert interacts with the component. (Subsidiary Ceratizit USA Inc. is in Warren, Michigan.) Called High Dynamic Turning, this system is capable of machining almost all workpiece contours, with 40% higher feed rates in some cases, said Paul Höckberg, product manager for cutting tools. He said HDT also allows feed rates to be adjusted during a process and offers excellent chip control.

Ceratizit's FreeTurn tools are designed for HDT and feature a slim shank that allows quick, easy adjustment of the insert angle during the cutting process or between operations.

"The ability to adjust the angle opens the door to endless possibilities for a wide range of turning operations and applications," Höckberg said.

A single FreeTurn tool can be used for all traditional turning operations, including contour, face and longitudinal turning. He said turning with just one tool eliminates the need for tool changes and saves substantial money on tool types.

Consider a gear shaft with multiple diameters and angles that normally would require a broad range of tools to machine. With HDT, however, the ability to rapidly change the approach angle during the cut or between cuts makes it possible to machine the entire component with a single tool, Höckberg said.

"It is even possible to have different radii on a single insert," he said, "allowing one tool to handle both roughing and finishing operations."

With conventional turning, generated forces are directed more or less perpendicular to the tool. During HDT, by contrast, the main cutting force is directed through the tool and into the spindle.

"This reduces vibration and allows for an optimal force distribution," Höckberg said.

HDT-ready machines must have an integrated mill spindle with a y-axis and a control system for positioning on that axis. Software requirements include five-axis simultaneous function and y-level cutting radius compensation. He said Ceratizit is working closely with an assortment of software partners to develop products that help users quickly and efficiently program machines for HDT and FreeTurn tools.

So far, a couple of software developers have come up with "adequate" offerings, Höckberg said, but "you can't just click 'High Dynamic Turning' and have the software spit out the programming in an optimized way. Solutions like that are not available at the moment."

Comparing HDT with PrimeTurning and rollFeed, he said the other systems don't offer 360 degrees of rotational freedom.

In addition, HDT "offers way more flexibility," Höckberg said. "Our system is so flexible that our tooling can be used in PrimeTurning operations, as well as a wide range of diverse additional operations."

For more information about these three turning technologies, view a video presentation here: cteplus.delivr.com/2ty4d