Shop considers investing in 5-axis machining

Shop considers investing in 5-axis machining

If your shop makes parts that demand multiple setups, parts that have challenging geometry or parts with difficult GD&T requirements, 5-axis machining could provide significant benefits. Do not let the potential cost of the investment prevent you from conducting a thorough cost analysis of your current machining methods.

When I started my career in machining, it was common to find machine shops that did not have CNC machines. My family's shop, for example, did not get its first machining center until 1995. We paid what felt like a king's ransom for a small, 3-axis vertical machining center before adding another machining center and, eventually, 2-axis turning centers.

Image courtesy of Hurco.

What really made a difference was the addition of a rotary table as the 4th axis. Being able to reach multiple sides of a part in a single setup gave us a competitive edge. From that point onward, every machining center we purchased had a 4th axis.

Four-axis machining centers became the norm at our shop, but over time it became apparent that 5-axis machining was the holy grail. Five-axis machining was an elusive goal for our shop—the investment required, coupled with the commoditized nature of the parts, seemingly did not justify the expense.

On many occasions, we discussed the potential ramifications of purchasing a 5-axis machine. Ultimately, we decided against it.

Considerations

We studied how 5-axis machining related to the geometry of the parts we manufactured and how we would operate a 5-axis machine. Our parts were simple compared with those produced by other manufacturers. Aerospace parts like jet engine blades and medical parts such as replacement joints are complex and often require simultaneous machine tool motion in all five axes. (Machining in more than one axis is called interpolation.)

A simpler form of 5-axis machining is referred to as 5-sided, or 3+2, machining. With this approach, a part is manipulated so five sides of a part are accessible, but interpolation in all five axes is not necessary to complete the geometry. Consider a cube that has a feature machined on the top and each of the four sides; the machine turns the part so each side is positioned for the tool to perform its work.

Next, we considered the dimensional tolerances of our parts. Five-axis machining makes it easy to hold close dimensional tolerances on multiple faces. Traditional machining methodology requires multiple workholding devices to access all faces. Having a setup with multiple coordinate systems, multiple workholding devices and numerous setups makes troubleshooting dimensional errors difficult.

Five-axis machining makes it easy to hold close dimensional tolerances on multiple faces. Image courtesy of Heller Machine Tools.

Besides reducing the number of workholders needed, 5-axis machining allows access to multiple sides without moving the part. Therefore, errors introduced from fixtures, multiple machining origins and other setting errors are eliminated. Troubleshooting problems with true position and other geometric errors is much easier when using only one workholder and one coordinate system.

Another consideration is inspection methods for 5-axis parts. Complex geometries are not only difficult to machine—they can be difficult to inspect. Geometric dimensioning and tolerancing (GD&T) requirements found on complex parts often necessitate using a coordinate measuring machine. Although most shops debating the merits of 5-axis machines have a CMM, it is still a consideration as CMM software and hardware upgrades may be necessary to support inspection of complex geometry.

Software and Style

When my family's shop bought its first machining center, we did not purchase CAM software to program the machine. Programming was done at the machine with a calculator, notepad and pencil. However, our parts were relatively

simple and did not require CAM software. For most shops, moving to 5-axis machining will likely call for purchasing new or upgraded CAM software.

Five-axis CAM software adds another level of cost and should be considered before purchasing a 5-axis machine. Software can easily cost $10,000 for a single 5-axis license, and it may be necessary to send programmers off-site for training.

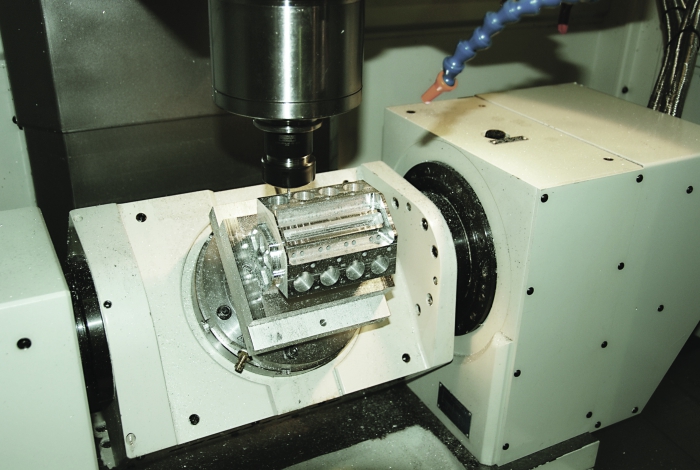

Finally, we had to consider the style of machine we would buy. Five-axis machines come in distinctive styles. Some have a spindle mounted in an articulating head. Others have a trunnion with a rotating table that tilts in the X-Y plane. The simplest, most economical versions put a 2-axis rotary unit on a 3-axis machine's table. All styles have unique advantages.

Trunnion-style machines were best for our parts. This style minimizes interference among cutting tools, workholders and the machine, allowing for short, rigid tools and compact setups.

Machines with articulating heads were too large for our parts and more expensive. We considered purchasing a 3-axis machine and installing a 2-axis rotary unit, but we were concerned that integrating two components that were not designed as a system would cause reliability issues. (I learned later, through experience, that a 3-axis machine with a 2-axis rotary unit can work very well.)

Five-axis technology can seem difficult to justify financially. Like many other machine shops, we were intimidated by the costs of 5-axis machining and chose not to adopt the technology, ultimately preventing us from gaining an advantage over our competitors. If your shop makes parts that demand multiple setups, parts that have challenging geometry or parts with difficult GD&T requirements, 5-axis machining could provide significant benefits.

Do not let the potential cost of the investment prevent you from conducting a thorough cost analysis of your current machining methods. It is possible you will discover that investing in 5-axis machining is easily justified.