Steady in the pocket

Steady in the pocket

Eliminate premature insert breakage and premature wear when facemilling. A facemill body with pockets that accurately seat inserts.

END USER: Venture Machine & Tool Inc., (608) 783-8114, www.vmtooling.com.

CHALLENGE: Eliminate premature insert breakage and premature wear when facemilling.

SOLUTION: A facemill body with pockets that accurately seat inserts.

SOLUTION PROVIDERS: A-Line Machine Tool Co., (608) 785-1515, www.alinetools.com; Toolmex Industrial Solutions, (800) 992-4766, www.toolmex.com.

Facemills take a lot of abuse when machining the tool steels, cast iron, prehardened 4140 steel and other metals Venture Machine & Tool Inc. uses to make its progressive dies, draw dies and stamping dies. The Onalaska, Wis., company is also a stamping house, using what it machines to run production for many customers.

Similar to the additional pain a quarterback endures when his team has a weak offensive line, the abuse is amplified when the carbide inserts do not sit securely in the pockets of the cutter body. Brian Atkinson, toolroom machinist for the tool and die shop, noted Venture was experiencing a significant amount of insert breakage and premature wear with facemills that allowed the inserts to reposition themselves in the pockets. In one 4 "-dia. facemill that accepted eight inserts, for example, that movement caused two inserts to sit farther out than the others, so the tool only used two cutting edges instead of eight and those two inserts were constantly breaking, he added.

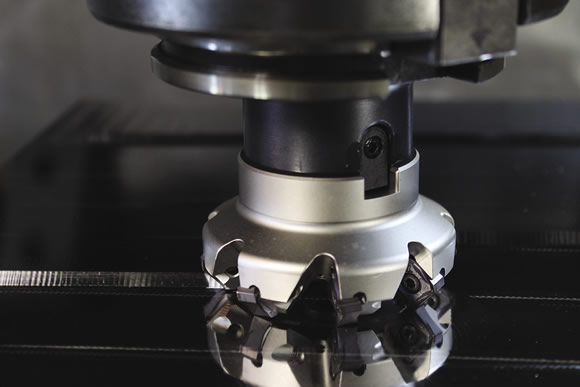

Palbit by Toolmex nickel-plated SNH facemills accept double-sided inserts with eight 45° cutting edges.

"You're not getting the same chip load per insert because you don't have a positive way to locate the insert in the cutter body," Atkinson said. "It's just a bad design. We would also have problems with surface finish, and it's not good for the machine."

Seeking a solution, Venture's local tool and equipment supplier, A-Line Machine Tool Co., La Crosse, Wis., introduced Atkinson to Matt Kersten, sales manager for Natick, Mass.-based Toolmex Industrial Solutions. The toolmaker offers the Palbit by Toolmex product line, and Venture added many of those tools to its lineup after testing them, including WNM high-feed facemills, AP90 10mm and 16mm indexable endmills, SCI tools for drilling 3 diameters deep and SNH facemills.

The SNH nickel-plated facemills accept double-sided inserts with eight 45° cutting edges and replaced the problematic cutters, which held single-sided inserts with four cutting edges. Atkinson pointed out that Venture tools the SNH facemills with Palbit by Toolmex grade-PH6920, submicron-grain, tungsten-carbide inserts coated with PVD titanium aluminum nitride.

According to Toolmex, the PH6920 inserts have high rake angles, allowing a positive cutting action on the tool for lower cutting forces. The combination of coating and substrate enhances toughness and wear resistance and provides a wide cutting speed range in almost every workpiece material without sacrificing tool life. Atkinson estimates that tool life improved 75 percent and the cutting speeds and feed rates increased more than 35 percent while still achieving the required surface finishes after switching to the SNH facemills, which range in size from 2 " to 6 " at Venture.

In addition, once the inserts are in the facemill body, they don't move out of the double-sided insert pocket design, which locks the inserts into the pocket similar to a dovetail joint, according to Toolmex. This takes the pressure off of the screw because the inserts cannot be pulled out the pocket, allowing Venture to consistently hold ±0.001 " tolerances, Atkinson added. "It's like when you find the right puzzle piece and snap it in."

Venture started applying the Palbit by Toolmex cutting tools in the toolroom and then expanded their use throughout the shop, with more applications expected in the future.

Atkinson said he calls the SNH facemills "bulletproof cutters" because they "can take anything you throw at them. Periodically, the guys who run some of these machines do something that would normally destroy a cutter, but the Palbit cutters take a lot of abuse and keep running."