Still more CNC lathe tips

Still more CNC lathe tips

Following the theme of the past two Shop Operations columns, here are some additional tips and tricks for operating a CNC lathe.

Following the theme of the past two columns, here are some additional tips and tricks for operating a CNC lathe.

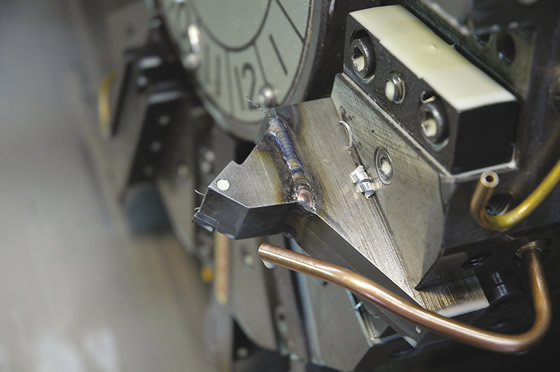

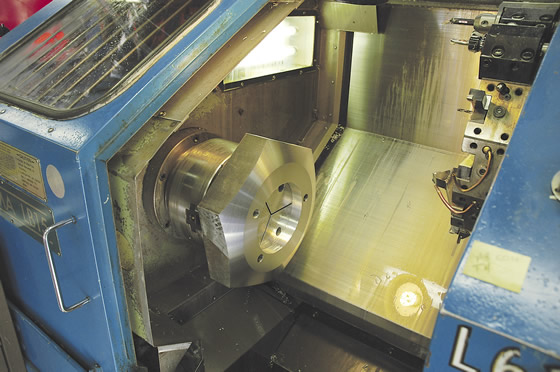

■ A handy trick for cutting diameters and parts outside the maximum turning diameter of a lathe involves a custom shop-made tool (Figures 1a and 1b). With this tool, I increased turning capacity from 9 " to more than 15 ". To create the tool, I cut the end off of a CCGX insert toolholder and welded it to a cold-rolled steel shank. Be sure to tack weld it first, then check the machine movement for the required clearances and travels before solidly welding it. This setup puts the tip much further back than what is possible with standard OD tools.

Figure 1a. This custom turning tool increases capacity on a CNC lathe.

Figure 1b. I used the custom turning tool to make this aluminum hexagon.

■ Figure 2 shows a method to proof programs and even verify part dimensions. I make several test blanks from medium-density fiber board laminated together with glue to get any blank size I need. I adhere the bandsawed laminations together with white carpenter's glue and then clamp them. MDF board is quite accurate in thickness and, more importantly, in flatness, and is cheaper and easier to use than huge blocks of wax or expensive butter board. It has no grain, so it is easier to cut than solid wood or plywood.

Figure 2. I make several test blanks from medium-density fiber board laminated together to proof programs and even verify part dimensions.

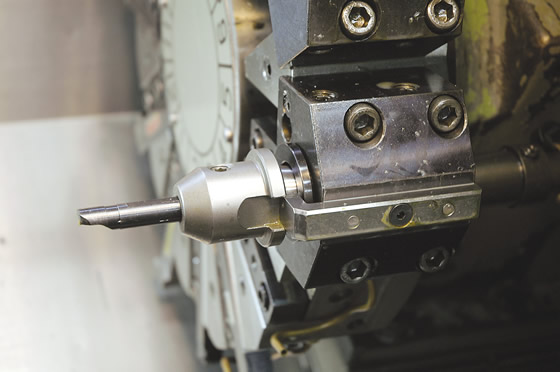

■ Figure 3 shows another lathe quick-change tool. Commercially available, quick-change tooling systems are quite expensive and don't lend themselves to highly varied job shop work. I had several special bushings made that match the taper of cheap and readily available endmill holders. These bushings have the required precision-ground tapers and locating keys, so the tool indexes accurately. The pictured holder is an NMTB holder, but almost any taper would work. I like the NMTB because it has a standard coarse thread for the retention knob. I just put a bolt in the back and I can switch between tools in seconds rather than minutes or hours.

Figure 3. An ID grooving tool is held in a quick-change system using a standard NMTB endmill toolholder. This quick-change setup is generally for ID tools, which typically take a long time to set up in a CNC lathe.

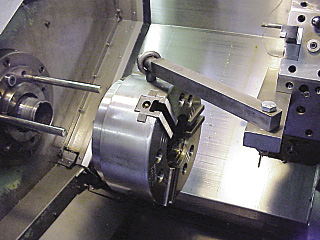

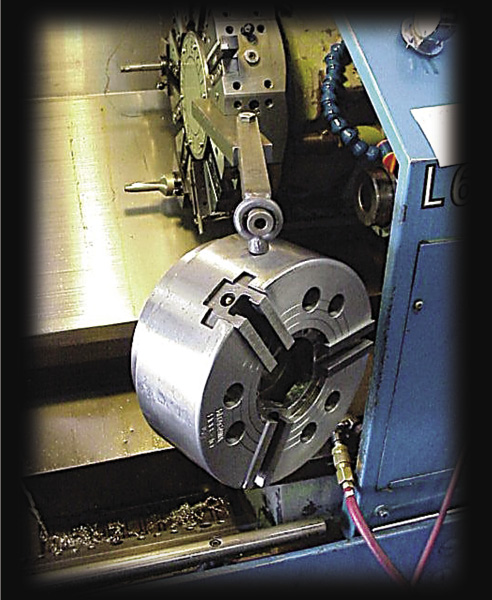

■ Changing the power chuck on a large CNC lathe can be a real hassle. I made a special for helping reduce changeover time from chuck to collet closer to 30 minutes instead of an hour or more (Figure 4). This pivoting tool clamps in an unused tool position in the turret, and the turret is jogged around to help remove or reposition the chuck. Once the chuck is off the hydraulic drawtube, the chuck can be swung out the door. In Figure 5 (page 38), the chuck is going on the machine. I use two guide pins that fit the retaining bolt hole minor diameter to guide the chuck into position and align with the drawtube.

Figure 4. This special helps reduce changeover time from chuck to collet closer to 30 minutes instead of an hour or more.

Figure 5. Once the chuck is off the hydraulic drawtube, the chuck can be swung out the door.

■ Spray some WD-40 on the inside of the window of a CNC lathe to help keep the window somewhat clear when testing a program. Anyone who has desperately tried to see clearly through the coolant shower while testing a new program will appreciate this tip.

Many of the tips I presented about CNC lathes are related to setup reduction, because a long setup is a roadblock to using a CNC lathe for every job at a machine shop. There is a breakeven point with the setup that depends on part configuration and volume. I would love to run all lathe work through a CNC lathe, but it is just not possible, at least not for our shop and workload. The CNC lathe is a fantastic tool, but I'm glad it's paid for and does not have to produce chips all day long to pay for itself. CTE

About the Author: Tom Lipton is a career metalworker who has worked at various job shops that produce parts for the consumer product development, laboratory equipment, medical services and custom machinery design industries. He has received six U.S. patents and lives in Alamo, Calif. For more information, visit his blog at oxtool.blogspot.com and video channel at www.youtube.com/user/oxtoolco. Lipton's column is adapted from information in his book "Metalworking Sink or Swim: Tips and Tricks for Machinists, Welders, and Fabricators," published by Industrial Press Inc., South Norwalk, Conn. The publisher can be reached by calling (888) 528-7852 or visiting www.industrialpress.com. By indicating the code CTE-2014 when ordering, CTE readers will receive a 20 percent discount off the book's list price of $44.95.