Still more tips for a manual mill

Still more tips for a manual mill

Continuing and concluding the theme of my previous two columns, this month's installment provides additional tips for enhancing the operation of a manual milling machine.

Continuing and concluding the theme of my previous two columns, this month's installment provides additional tips for enhancing the operation of a manual milling machine.

• For working on large plates, make a couple of spreader bars. The spreader bars have counterbored bolt holes on the same centers as the T-slots. Make the spreader bars out of something relatively soft so they can be sacrificial.

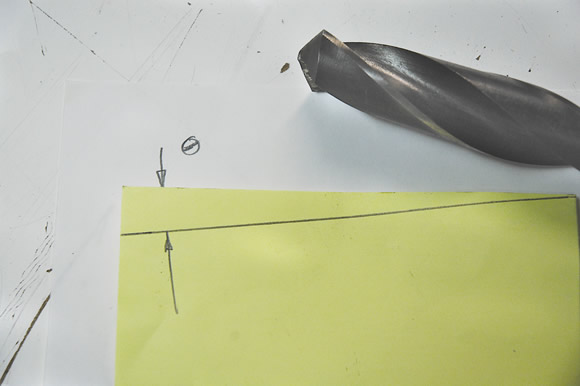

• Rounding the corners of a standard drill bit with a honing stone enables the drill to impart a finer hole finish. This is a sneaky way to get around not having an odd reamer size. You can also manually grind a twist drill a bit off-center to have it cut a whisker larger.

Use a honing stone to round corners on a drill to impart a finer hole finish when you don't have an odd-size reamer.

A slip of paper can be used to measure and indicate the back clearance, or relief, angle on a drill bit.

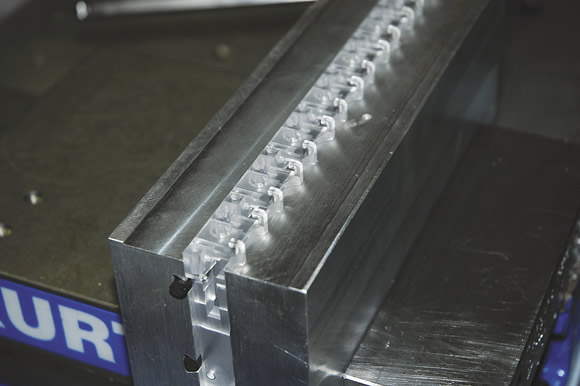

A cutoff piece or O-ring cord stock provides the right amount of squeeze and friction to securely hold multiple parts.

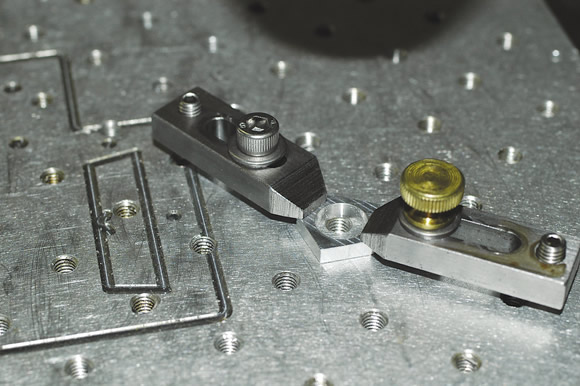

You can use a drill chuck as a hand tapping guide if you leave the collet loose.

Strap clamps hold a small part on a subplate.

• A simple way to measure the back clearance, or relief, angle of a hand-ground drill bit is to use a little slip of paper. Wind the paper around the cylindrical part of the drill body and mark the point where the corner meets the edge of the paper. The angle formed by these points is the clearance angle.

• With an oversize table on a vertical mill, you can have more than one setup on the machine. Wipe the dovetails clean all the way to the ends of the travels and make use of that extra work envelope.

• Put a short wrench on the vise to keep apprentices from overtightening setups. Use the clock method to describe the handle position. Tell them, "Tighten this to 3:00 exactly. Not 2:30 or 3:30."

• You can use a drill chuck as a hand tapping guide if you leave the collet loose. Don't forget to lift it up before you move to the next hole.

• Get a cheap air ratchet for changing chuck and vise jaws. Replace the mounting screws with shorter ones to reduce spinning time. Be sure to take any cutting tools out of the spindle because the air ratchet can buck your hand into the tool if you're not ready for the torque reaction.

• Use some soft aluminum filler rod to help secure multiple parts. The soft, round wire squeezes down and makes up for the small differences in part width. This trick works best on hard parts, such as ones made of stainless steel, that require a fair amount of clamping pressure. Vertically position the soft wire for multiple stacked parts.

• Using a standard dovetail O-ring groove cut into a soft jaw face is another great trick for securely holding multiple parts. A cutoff piece or O-ring cord stock provides the right amount of squeeze and friction to hold the parts. You can also use different O-ring materials for different types of part holding.

• One of the best things I ever made was a 6 "×6 " subplate with small strap clamps for holding small parts. You can also screw a parallel or a sheet metal V-plate to the subplate as a fence when you are making multiple parts.

• For accurate true position location, drill undersized and then use a single-point boring tool to establish the true centerline of the hole. After a light cleanup, cut with the boring head, finish ream the hole to size. As an alternative, drill and follow with an endmill plunge. CTE

About the Author: Tom Lipton is a career metalworker who has worked at various job shops that produce parts for the consumer product development, laboratory equipment, medical services and custom machinery design industries. He has received six U.S. patents and lives in Alamo, Calif. Lipton's column is adapted from information in his book "Metalworking Sink or Swim: Tips and Tricks for Machinists, Welders, and Fabricators," published by Industrial Press Inc., New York. The publisher can be reached by calling (888) 528-7852 or visiting www.industrialpress.com. By indicating the code CTE-2013 when ordering, CTE readers will receive a 20 percent discount off the book's list price of $44.95.