Still more tips for operating a CNC mill

Still more tips for operating a CNC mill

The Shop Operations column suggests that you should use every tool, trick and option at your disposal to get jobs out the door as quickly as possible because speed and momentum reduce costs when applied to part processing.

Continuing the theme of the past two columns, here are additional tips for enhancing the operation of a CNC milling machine. Because speed and momentum reduce costs when applied to part processing, you should use every tool, trick and option at your disposal to get jobs out the door as quickly as possible.

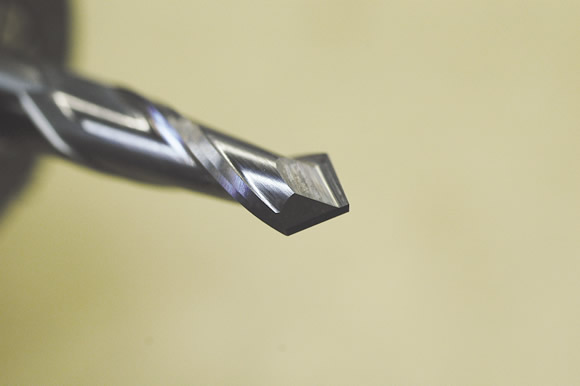

Drill-point endmills enable you to drill, mill and chamfer.

■ If you are planning or rearranging your CNC shop, be sure to include a water hose bib near the machines. Machines that operate all day long lose a significant amount of coolant to evaporation. This can be made up by adding water or a makeup solution of your water-based coolant to maintain the correct concentration.

■ Plumb a quick disconnect in line with your coolant line. If you make a short hose with a spray nozzle, it can be used to wash the inside of a machine after a job. This also makes it easier to steal some coolant from another machine in a pinch.

■ Apply cutting tools as long as possible to reduce cycle times. You can drill, mill and chamfer, for example, with a drill-point endmill. Sometimes a subtle change in tool selection will allow a tool to be used for several operations, eliminating the need for tool changes and noncutting time. This tip is valid even for rapid tool changes. Vertical machining centers typically have less-than-stellar spindle utilization, so anything you can do to keep the tool in the cut is a good thing.

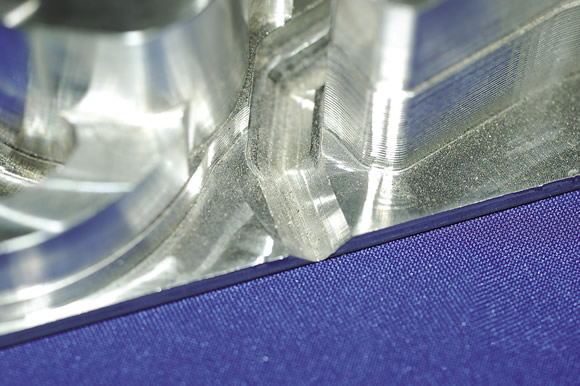

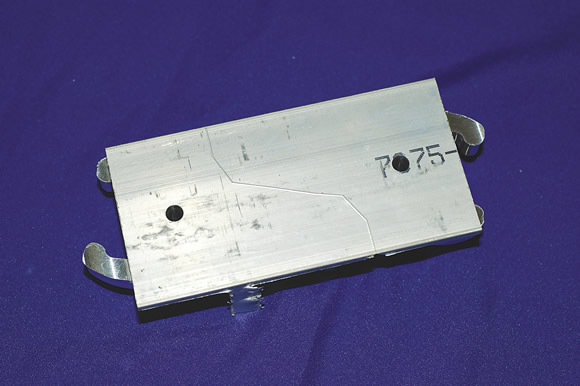

■ A trick for separating multiple ganged parts involves applying a 90° chamfer mill or drill-point endmill to follow a contour that will be the parting line between the parts. Leave 0.001 " to 0.003 " of material at the bottom for an easy break line on the back of the ganged parts. Then, you can easily snap off the parts and insert them in pocketed soft jaws for second-side operations.

Top: A trick for separating multiple ganged parts involves applying a 90° chamfer mill or drill-point endmill to follow a contour that will be the parting line between the parts. Middle: Leave 0.001 " to 0.003 " of material at the bottom of the contour path for an easy break line on the back of the ganged parts. Bottom: Then, you can easily snap off the parts.

■ When circular interpolating, use a boring head to achieve the roundest possible holes. Single-point boring is still the most accurate method for achieving true position and hole roundness. Use single-point boring for precision bearing bores and where critical true position is required, such as with gear meshes and linear bearing bores.

■ If you're having problems with hole roundness or true position when circular interpolating, try slowing the feed rate for the finishing pass to even out the quadrant mismatches. Even with high-speed controls, this trick will sometimes give you more consistent results. If your plug gage rocks in one direction when you test a hole, it is a sign the hole is not as round as it could be.

■ You can use out-of-roundness to your advantage. For sliding fits, where sliding parts are fitted together, a few tenths of out-of-roundness provides an air vent for a blind-hole or a place for lubricant to reside.

■ Keep a machine-dedicated logbook at each machine and CAM station to record problems and maintenance practices, among other notes. It also provides a great place to store all the little quirky bits of information related to each machine, such as "check Y-axis limit switch if you get error 1234." If you need to call outside help, the logbook can be a valuable source of machine history for the technician. If you record information such as metal-removal rates for different tool types, these logbooks can also be a great training aide. This information has become the gold standard of operations, helping at every level—from the shop floor to engineering and estimating. On that same note, read the logbooks occasionally and see what kinds of information are being recorded. If it's worth writing, it's probably worth reading.

■ Document and laminate company setup and operation procedures for each machine. This will pay big dividends when training new operators. Keep the length to one operation or task per sheet, and then title the sheets. Some examples include: setting tool offsets, restarting a program at a particular line and adjusting wear offsets.

■ You never seem to have as many tool totes as you'd like. I feel the available totes for CNC toolholders are overpriced, which makes stocking up on them painful for small shops. Our sheet metal shop made some totes from ⅛"-thick aluminum. They are more compact than commercial units and dirt cheap to make. A tote allows you to "kit" a job's tools ahead of time or efficiently store the exact tools for a repeat job. I even haul these into the CAM area when programming to make sure I have everything thought out correctly. CTE

About the Author: Tom Lipton is a career metalworker who has worked at various job shops that produce parts for the consumer product development, laboratory equipment, medical services and custom machinery design industries. He has received six U.S. patents and lives in Alamo, Calif. For more information, visit his blog at oxtool.blogspot.com and video channel at www.youtube.com/user/oxtoolco. Lipton's column is adapted from information in his book "Metalworking Sink or Swim: Tips and Tricks for Machinists, Welders, and Fabricators," published by Industrial Press Inc., South Norwalk, Conn. The publisher can be reached by calling (888) 528-7852 or visiting www.industrialpress.com. By indicating the code CTE-2013 when ordering, CTE readers will receive a 20 percent discount off the book's list price of $44.95.

About the Author: Tom Lipton is a career metalworker who has worked at various job shops that produce parts for the consumer product development, laboratory equipment, medical services and custom machinery design industries. He has received six U.S. patents and lives in Alamo, Calif. For more information, visit his blog at oxtool.blogspot.com and video channel at www.youtube.com/user/oxtoolco. Lipton's column is adapted from information in his book "Metalworking Sink or Swim: Tips and Tricks for Machinists, Welders, and Fabricators," published by Industrial Press Inc., South Norwalk, Conn. The publisher can be reached by calling (888) 528-7852 or visiting www.industrialpress.com. By indicating the code CTE-2013 when ordering, CTE readers will receive a 20 percent discount off the book's list price of $44.95.