Toolholders a critical connector

Toolholders a critical connector

Match toolholders with the correct application to maximize performance.

Toolholders are the critical connection between a cutting tool and a machine tool spindle. Toolholder performance dictates productive output, surface finish of a part and the life of a cutter. With the right toolholder for the application at hand, a shop maximizes benefits from high-performance cutting tools and machine tools.

Different toolholder types provide different levels of performance. Depending on the machining application, some performance factors are more important than others. For precise work, a low total indicator runout may be most important. When multiple setups are involved, quick-change capability is essential to maximize productivity. In heavy-cutting situations, tool retention force might be emphasized. And in most operations, the cost of the tooling system itself is a significant factor.

When it comes to the various toolholders and their qualities, ER collets are known for gripping strength and accuracy. Collets in the ER system, which was introduced in the early 1970s by Rego-Fix Tool Corp., Whitestown, Indiana, and later standardized as DIN 6499, supply a wide clamping range and high accuracy over an extended selection of operations.

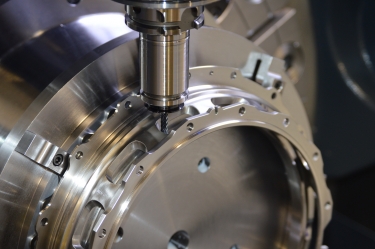

Toolholders are the critical connection between a cutting tool and a machine tool spindle. Image courtesy of Rego-Fix Tool

Most shops select toolholding systems based on the parts being made and how they are manufactured. Depending on the product mix, shops generally use more than one holding system. An effective way to simplify toolholder selection and acquisition is with a family of toolholding technologies, such as those developed by Rego-Fix Tool. Its original ER clamping system — composed of an ER collet holder, a collet and a nut — is engineered for traditional machining applications while its powRgrip system is aimed at high-speed milling and drilling and other high-performance applications. The latter system consists of powRgrip toolholders with internal tapers that accept the matching tapers of powRgrip collets. Tools are inserted into and removed from the holders using a fast-acting manual or automatic hydraulic powRgrip unit.

For tougher machining operations, secuRgrip toolholders are made to fit powRgrip clamping units and prevent cutter pullout. This method utilizes a patented locking system and threaded cap, with the key element being a special collet configured to accept a threaded insert that locks into the Weldon flat on any tool with that feature. The system has a total indicator runout of 0.00254 mm (0.0001"). No tool shank modification is required, and existing powRgrip holders can be modified for use with these holders.

At the opposite end of the toolholding size spectrum, the micRun system handles small-tool, micromachining applications, such as those found in the watch-making and medical industries. A symmetrical design without grooves or flats minimizes vibration, and special threads keep the nut aligned with the holder for maximum rigidity and repeatability. The system provides runout of ≤3 µm (0.0001") at 3 diameters deep, which enhances machining quality, overall productivity and tool life in high-precision applications.

No toolholding system is perfect for every machining circumstance. However, toolmakers have focused their tool development efforts to create systems that enable high productivity and cost efficiency across the wide range of manufacturing situations.