Using stability lobe diagrams

Using stability lobe diagrams

Machine Technology column for May 2009 issue of Cutting Tool Engineering

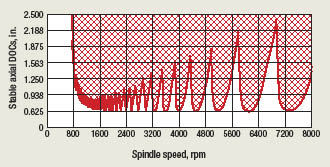

Do you recognize the diagram below? You should, because it represents the productivity of your machine tools. It's a stability lobe diagram and it summarizes cutting performance in metal-removal operations. This specific diagram was made for milling with a 2-flute carbide endmill in a 40-taper shrink-fit holder in a 7,200-rpm machining center. It was made for a particular radial DOC (in this case slotting) in 7050 T-7451 aluminum.

Courtesy of Manufacturing Laboratories

A typical stability lobe diagram.

The cutting conditions in red-shaded areas will cause chatter, characterized by heavy vibration, tool damage, poor surface quality and scrapped workpieces. The conditions in the white areas will be stable, producing no chatter.

When spindle speed is low enough, less than about 800 rpm in this case, it is possible to take large axial DOCs without causing chatter. As spindle speed increases, the chatter-free axial DOC decreases, in this case to about 0.3 " in the 1,600-rpm range. Any slots deeper than this will cause chatter. As the spindle speed increases further, the permissible axial DOC increases again, but only in specific spindle speed ranges. For example, there are large, stable pockets around 4,800 to 4,900 rpm, around 5,600 to 5,700 rpm and around 6,700 to 6,800 rpm. There will be another pocket near 8,400 rpm as well, but that is higher than the top speed of this spindle.

At the best of these speeds, the axial DOC can be more than four times higher than at the worst speeds. The metal-removal rate and the machine productivity can be greatly increased by using the right spindle speed. The stable pockets get taller and wider as the spindle speed increases, which is one of the major factors driving machine tool builders and users toward high-speed machining.

A stability lobe diagram like this one can be created for every tool in every toolholder in every machine. I say "like this one" because although all stability lobe diagrams have similar characteristics, details differ for each application because assembled structures differ.

Chatter arises from a dynamic interaction between the cutting process and the machine structure. The machine structure is stiff, but not infinitely so. As the cutting tool's teeth pass the workpiece, deflections between the tool and workpiece leave an imprint, or waviness, on the surface. The following teeth encounter the waviness and experience a variable cutting force, which causes vibration and leaves another wavy surface. Depending on the characteristics of the assembled structure and on the cutting conditions, the waviness can get worse, producing chatter, or it can improve, becoming more stable.

Knowing where the "good" speeds are and knowing the permissible DOCs can allow operators to double or triple mrr without any modification of the existing tools, toolholders or the machine. However, nearly every part of the machine structure plays a role in the specific appearance of the stability lobe diagram, including the:

• length and diameter of the tool,

• number of cutting edges,

• tool/toolholder interface,

• toolholder style,

• toolholder/spindle interface,

• drawbar force,

• size, material and arrangement of the spindle bearings,

• maximum spindle speed, and

• torque and power curves.

It is the performance of the assembled machining system that counts, not any one piece. There is no general chatter-free tool, no best number of teeth and no best kind of toolholder.

There is also no general best machine, spindle interface or spindle speed. Rather, all of the machining system's elements contribute to the stability lobe diagram. While suppliers of machines, tools and toolholders try to optimize their specific products, it is not until the pieces come together at the process that the performance is determined. Some tools and holders match one machine or process better than another. Sometimes, large stable zones correspond to the programmed spindle speeds, but far more often this is not the case.

The stability lobe diagram controls the performance of milling and many other metal-removal operations. Without the stability lobe diagram, machine tool users are guessing, and guessing represents a huge productivity loss. Trial-and-error programming, selection of unproductive cuts, scrap and damage to the machine are the hidden costs of insufficient information. Competitive shops need stability data for all their tools in all their machines. Stability lobe diagrams are a powerful key to unlocking the full potential of machine tools. (Note: Future columns will examine the information needed to create stability lobe diagrams and how shops can develop them or have them developed.) CTE

About the Author: Dr. Scott Smith is a professor at the William States Lee College of Engineering, University of North Carolina at Charlotte, specializing in machine tool structural dynamics. Contact him via e-mail at [email protected].