Xtra·tec XT - Performance extends your perspective

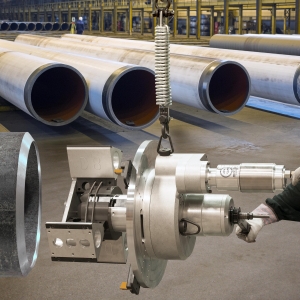

Walter has introduced its next generation of milling tools: the Xtra·tec® XT (XT stands for "Xtended Technology"). Designed to achieve increased productivity and process reliability, this new generation of milling cutters is being launched with initial offerings of shoulder milling cutters and a face milling cutter. The mills cover virtually all requirements in shoulder and slot milling for all common material groups.