Milling Cutters

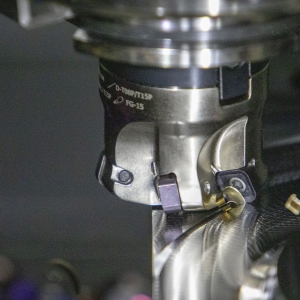

DoTriple-Mill | Multi-Functional Face Milling Cutter with High Rigidity

DoTriple-Mill is Tungaloy’s face milling cutter featuring a dovetail clamping system that dramatically reduces insert lift up and excessive shear force imposed on the screws during heavy duty milling. Three types of inserts fit in the same cutter body, making it the perfect cutter when various materials have to be machined and machine tool settings are limited. A bore type cutter body is available in coarse and close pitch designs, and the standard tool diameter ranges from 2.00" to 6.00" (and in metric sizes 50 to 160 mm).