Milling Cutters

ANCA ToolRoom RN34 aimed at aerospace, die mould, general machining, power generation industries

Watch the video to see how ToolRoom RN34 — a specially designed software package for the aerospace, die mould, general machining and power generation — can help you design and manufacture complex tool geometries and getting them balanced perfectly for optimal cutting conditions. New features include: endmill cycles for ballnose and corner radius, tool balancing and next generation fluting cycles.

For more information visit us at https://machines.anca.com/ToolRoom-RN34-demo

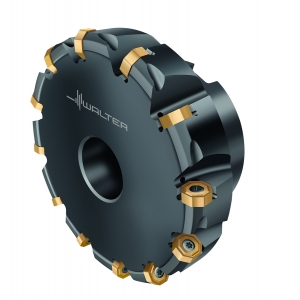

Iscar T-Face: Maximum productivity for face milling applications

ISCAR has introduced T-FACE, a new family of tools for applications that require small to mid-diameter face mills (1.25”, 1.50” & 2.00”).

MC Molds: “We’re making chips in a matter of minutes.”

Manufacturing and machining rotary tools with VOLLMER: efficient and precise!

The VGrind 360, VOLLMER’s latest tool grinding machine, is equipped with enhanced travel distances in order to machine carbide tools up to a diameter of 100 millimeters. Thanks to its two vertical spindles, the VGrind 360 also allows for tried-and-tested multi-level machining. This enables tool manufacturers to quickly and precisely produce large numbers of milling cutters, drills, etc. whose blanks are made from either solid carbide or HSS (high speed steel).

Learn How IC Drills Help Conquer More Difficult Drilling Dilemmas

Why do indexable carbide drills excel in more extreme drilling applications? To find out, watch Allied’s senior product manager and engineering trainer team up to demonstrate.

Difficult drilling applications in this educational, 5-minute clip include:

Achieve Fast Stock Removal with P.B.S. Braze Bond Grinding Products

Abrasive Technology’s P.B.S.® braze bond grinding products promote high diamond exposure with optimal coverage for aggressive tooling that lasts longer, cuts faster and runs cooler. Our proprietary P.B.S.® process eliminates peeling and diamond pull out, making these products ideal for machining tough-to-cut materials where fast stock removal and deep cuts are required.

For more information visit us at http://www.abrasive-tech.com/