Milling Cutters

Contact Details

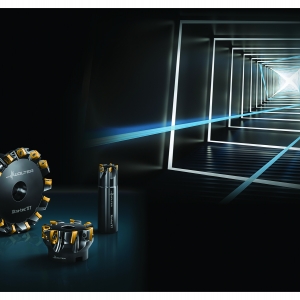

MFH-RAPTOR High-Feed Facing, Slotting, and Helical Interpolating

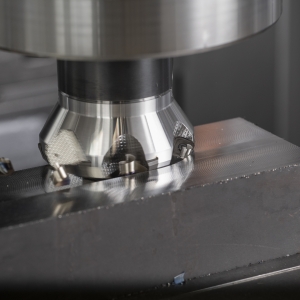

Kyocera’s MFH-RAPTOR high-feed milling series allows for full radial engagement and high feed rates. This makes it possible to quickly and efficiently face off large surface areas. Using an MFH3000R14-6 face mill with FL chipbreaker shown in the video leaves an excellent 7.79 Ra surface finish. The MFH-Mini can also machine deep slots using a unique convex edge design for smooth entry into the workpiece which reduces vibration and provides excellent chip evacuation.