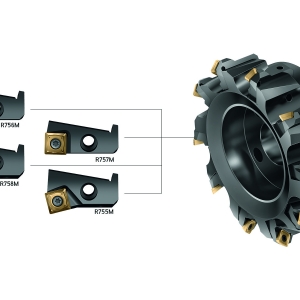

Milling Cutters

Dormer Pramet product tour traverses planes, trains and more

Brian Norris, president of The Americas for Dormer Pramet, spent a few minutes during IMTS 2018 to guide Cutting Tool Engineering Publisher Dennis Spaeth through a number of product highlights from Precision Twist Drill, Union Butterfield, Dormer and Pramet.

Among the highlights: