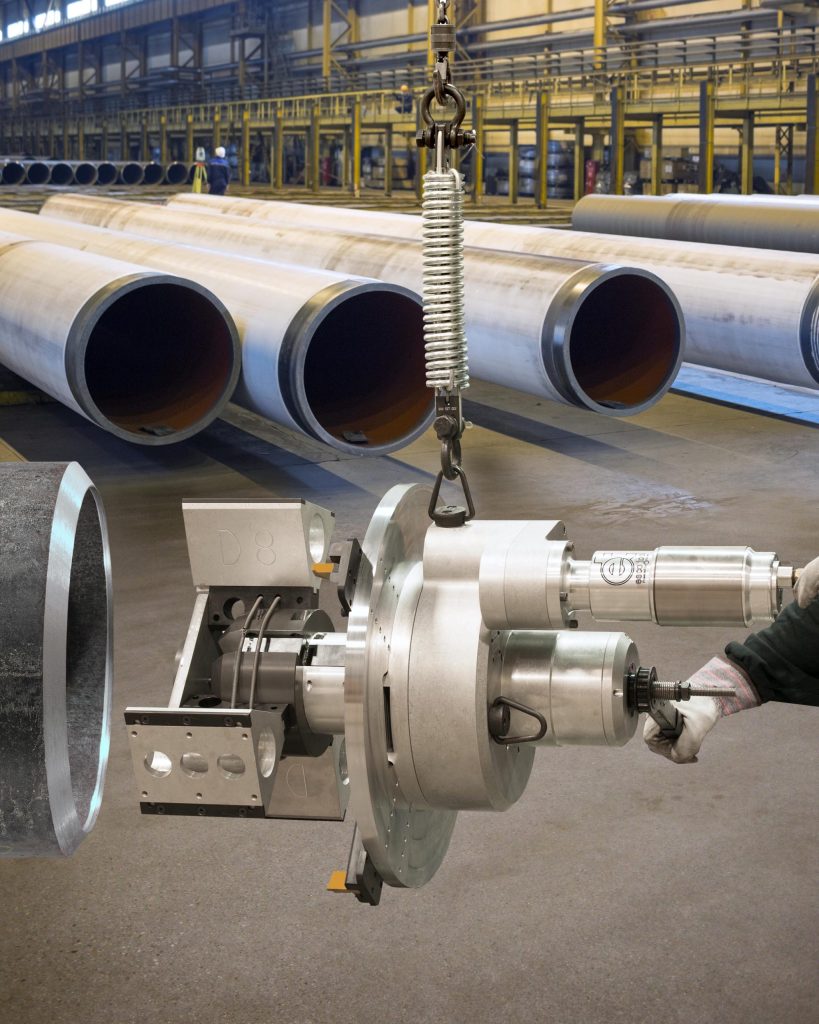

Dictator II MILLHOG Pipe Beveler

Dictator II MILLHOG Pipe Beveler

A new pipe beveling tool with an operating range from 4.5" ID to 24" OD that requires only one mandrel and 10 clamps for the entire range of the tool has been introduced by Esco Tool. The Dictator II MILLHOG Pipe Beveler uses one mandrel and a set of three wide clamps that provide six points of contact on the pipe ID, resulting in rigid mounting and chatter-free beveling for a given pipe size range.

A new pipe beveling tool with an operating range from 4.5" ID to 24" OD that requires only one mandrel and 10 clamps for the entire range of the tool has been introduced by Esco Tool. The Dictator II MILLHOG Pipe Beveler uses one mandrel and a set of three wide clamps that provide six points of contact on the pipe ID, resulting in rigid mounting and chatter-free beveling for a given pipe size range.

Featuring only 10 sets of clamps, which are easy to change for the entire range of the tool, this beveler can perform any angle of prep on any type of pipe alloy and can bevel, face, and bore simultaneously.

Suitable for fabrication shops and on-site applications, the pipe beveler includes a patented safety spring hanger for easier alignment. Requiring no cutting oils, it uses the EscoLock cutter blade holding system and proprietary TiN-coated cutter blades that direct the chip and heat away from the pipe surface to prevent work hardening and extend blade life. Pneumatic, hydraulic and electric power are available.