Milling Cutters

Optimized M5 milling cutters from Sandvik Coromant

In this video overview, Sandvik Coromant introduces the complete series of M5 milling cutters developed for automotive aluminum machining. Made for more productive machine operations, the milling cutters offer everything from first stage machining to super finishing. Watch this demo and discover how these new milling concepts deliver minimized cycle times and prolonged tool life.

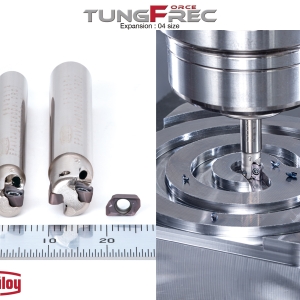

Roughing and finishing milling cutters from Mikron

Mikron Tool expands the CrazyMill Cool P&S milling cutter family developed for roughing and finishing operations with the addition of a toric (corner radius) version. The new tool, as shown in this video overview, combines the strengths of milling and drilling and is designed for machining stainless steel, titanium, CoCr alloys and superalloys.