Turning

Turn Right

The practice of turning threads on a lathe is well known but oftennot well-understood. Toolmakers offer their recommendations on how todo it the right way. By Bill Kennedy There are nearly as many ways to produce threads as there are types of parts that require them. Threads can be cut with a die, rolled, ground, tapped or milled, using lathes, machining centers or specialized machines.

Multitask Machines

Editor's Note: This video report is presented as a supplement to Cutting Tool Engineering's January cover story, "Down-hole, High-tech." The animation from Phillips Engineering Technologies was created to clearly illustrate the operation of a twin-ram vertical turning lathe.

Hard turning steel

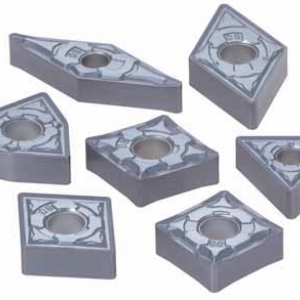

Video shows Becker CBN inserts being used to hard turn 62Rc d2 steel. The inserts are sold in the U.S. by Rani Tool Corp.