Mastercam’s 2022 Wildest Parts Competition winners

Mastercam’s 2022 Wildest Parts Competition winners

Mastercam announced its 2022 Wildest Parts Competition winners. The Wildest Parts Competition is held each year to encourage student interest and participation in manufacturing.

-1024x1024.jpg)

Mastercam announced its 2022 Wildest Parts Competition winners. The Wildest Parts Competition is held each year to encourage student interest and participation in manufacturing.

The competition is open to students at the secondary and postsecondary levels to create parts demonstrating creativity and technical skill using Mastercam. The Wildest Parts Competition also has a division for professional Mastercam users to enter parts they created.

"Each year, we look forward to seeing all the entries we receive for Wildest Parts," said Peter Mancini, Product Manager, Education at Mastercam. "There are so many talented and dedicated teachers, and the quality and originality of their students' work with Mastercam is both amazing and inspiring. The professional division lets instructors and machinists think outside the box and push their Mastercam skills to make something extraordinary."

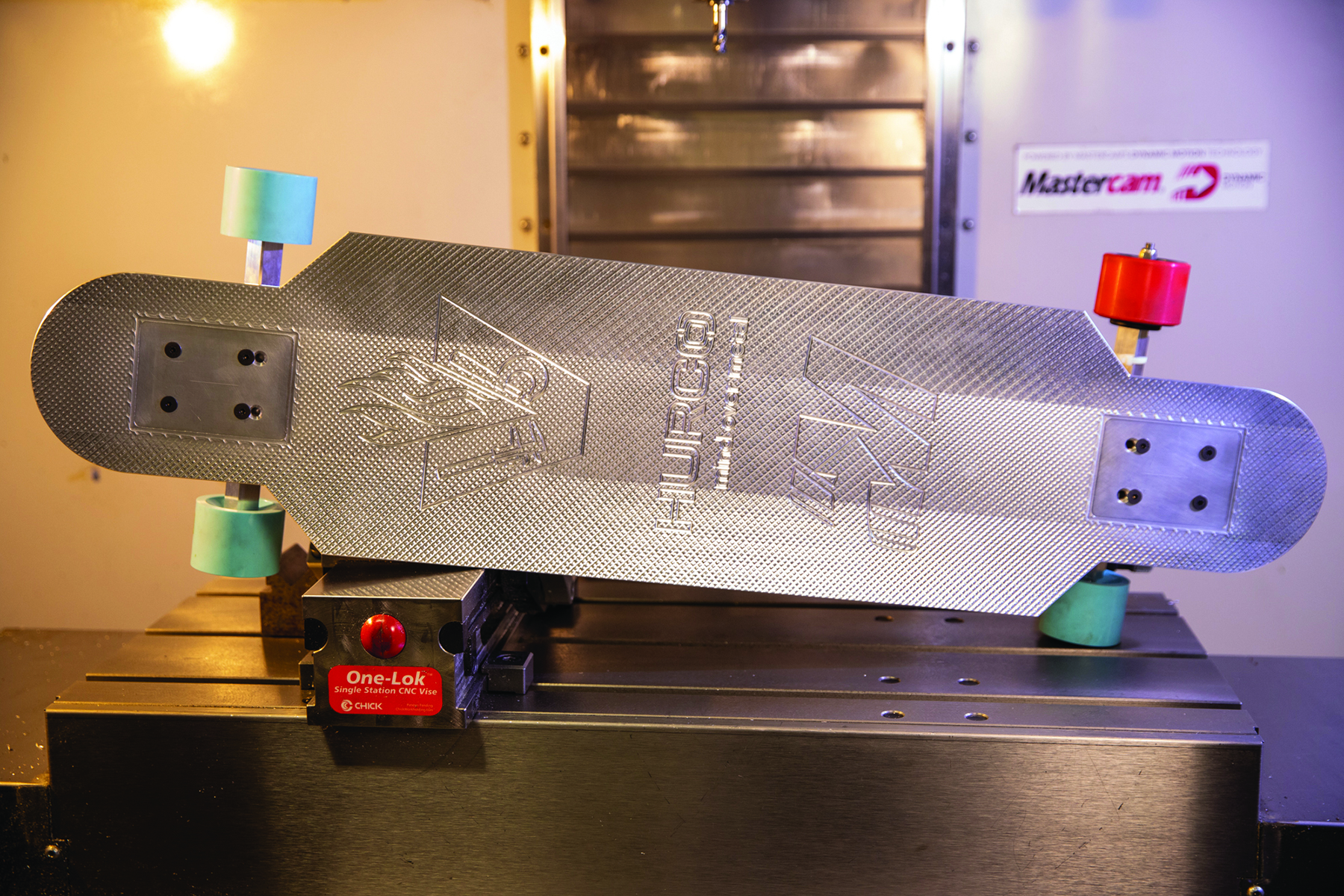

In the Educational Division, a team from Vincennes University, Indiana, submitted a working electric skateboard. The project started out as a simple personal project until their instructor approached them about entering it into the competition! The students designed and manufactured everything on the board except for the electronics. Second place went to a team from National Xinying Industrial Vocational High School, Taiwan, who designed a violin. They wanted to design a product that would change the 'cold' impression that people have of the manufacturing industry, so they created a violin that is full of enthusiasm and warmth. Third place went to Kwan Syn Yen from National Tsing Hua University (Taiwan), who submitted a combination/master lock in the shape of an end-mill, paying tribute to CNC manufacturing.

In the Educational Division, a team from Vincennes University, Indiana, submitted a working electric skateboard. The project started out as a simple personal project until their instructor approached them about entering it into the competition! The students designed and manufactured everything on the board except for the electronics. Second place went to a team from National Xinying Industrial Vocational High School, Taiwan, who designed a violin. They wanted to design a product that would change the 'cold' impression that people have of the manufacturing industry, so they created a violin that is full of enthusiasm and warmth. Third place went to Kwan Syn Yen from National Tsing Hua University (Taiwan), who submitted a combination/master lock in the shape of an end-mill, paying tribute to CNC manufacturing.

In the Professional Division, David Berry from Southwestern Illinois College submitted a turbocharged impeller, which was created to push his skills and complete a part that was beyond his current knowledge. David always wanted to cut an impeller, so he designed a desk piece that featured a 12-blade, large wheel compressor design. Tzu-Wen, Chen from Taichung Municipal Taichung Industrial High School (Taiwan) tied for 2nd place by submitting a squirrel family.

Mastercam and a 5-axis machine were used to make the squirrel, and the squirrel was a reminder to everyone living on the campus about the importance of ecological development and sustainability. Guan-Jun Fang from Taichung-Changhua-Nantou Regional Branch of the Ministry of Labor's Workforce Development Agency (Taiwan) also tied for 2nd place by submitting a rocket which consists of a basic, body, and connector and were all made on a Turning and Milling center out of aluminum.

Every participant receives a Mastercam t-shirt, and the winning entrants receive cash awards, certificates, and other prizes for entering the competition.