Autodesk Inc. announced the availability of HSMWorks 2014, the integrated CAM solution for SolidWorks users.

"Autodesk's goal is to create the world's best CAM tools and continue to provide users with the power and quality they have come to expect," said Robert "Buzz" Kross, senior vice president of design, lifecycle and simulation at Autodesk. "We are committed to offering customers both the ease-of-use and productivity advantages of professionally integrated CAM no matter what CAD software they use."

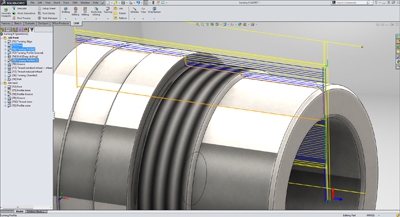

HSMWorks 2014 offers better control over existing toolpaths to produce high quality surface finishes and optimize use of standard cutting tools, and powerful enhancements to simulation and toolpath calculation capabilities that allow users greater visibility into the machining process and the ability to leverage more computing power across their organization, according to the company.

Additional new features include:

Machine Simulation — Support has been added for a wider range of machine types including 5-axis machining centers. Utilization of native SolidWorks assemblies means users are able to model their machines right inside SolidWorks software without having to import STLs or dumb solids.

HSMWorks API — The new API provides users with the ability to automate many programming tasks such as toolpath generation and post processing.

Adaptive Clearing 2.0 — Adaptive Clearing has set the bar for efficient, high volume material removal using a strategy of constant tool engagement to reduce cycle times, tool and machine wear, and produce quality finished parts. Enhanced multi-core support and improved linking make Adaptive Clearing 2.0 the most advanced adaptive roughing technology to date.

Enhanced Turning support — New options have been added giving users greater control over toolpath creation including finer controls over leads and transitions, overlaps, roughing, and finishing passes. Additionally, turning toolpaths have been optimized to reduce machining time by improving linking and ordering, as well as control over home and retract positions.

"From the beginning, we have focused on integrating HSMWorks CAM technology into our extensive portfolio of desktop and cloud-based design tools, while also continuing the development of the leading CAM solution for SolidWorks users, HSMWorks," said Kross. "This release delivers on that promise."

Contact Details

Related Glossary Terms

- centers

centers

Cone-shaped pins that support a workpiece by one or two ends during machining. The centers fit into holes drilled in the workpiece ends. Centers that turn with the workpiece are called “live” centers; those that do not are called “dead” centers.

- computer-aided design ( CAD)

computer-aided design ( CAD)

Product-design functions performed with the help of computers and special software.

- computer-aided manufacturing ( CAM)

computer-aided manufacturing ( CAM)

Use of computers to control machining and manufacturing processes.

- toolpath( cutter path)

toolpath( cutter path)

2-D or 3-D path generated by program code or a CAM system and followed by tool when machining a part.

- turning

turning

Workpiece is held in a chuck, mounted on a face plate or secured between centers and rotated while a cutting tool, normally a single-point tool, is fed into it along its periphery or across its end or face. Takes the form of straight turning (cutting along the periphery of the workpiece); taper turning (creating a taper); step turning (turning different-size diameters on the same work); chamfering (beveling an edge or shoulder); facing (cutting on an end); turning threads (usually external but can be internal); roughing (high-volume metal removal); and finishing (final light cuts). Performed on lathes, turning centers, chucking machines, automatic screw machines and similar machines.