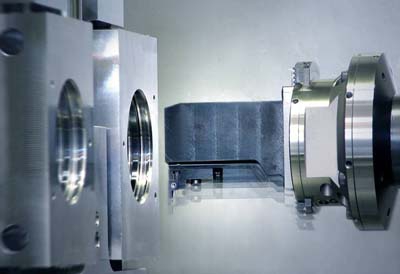

Heller Machine Tools announced the development of a technically and economically viable feed-out system that uses an additional axis to provide radial feed movement of the tool cutting edge. Compared to conventional solutions, the feed-out system reduces machining and idle times and much better process dependability. Besides the benefit of being an open system, the feed-out system has further advantages over add-on solutions offered by competitors: instead of requiring an individual drive for each facing head, Heller's solution only uses one drive incorporated in the machine. As a result, the cost benefit increases with the number of facing heads used. In contrast to any other feed-out system concept for integration into a machining center, the Heller feed-out system is a package solution that includes a drive, a connecting link (the adjusting shaft) and a facing head onto which any type of cutting tool can be mounted. Users of machining centers without the ability to perform turning operations had no other choice: the workpiece needed to be unclamped for further machining on a turning machine. Until now, there were only a couple different types of integrated solutions for use on a machining center. The first type is a conventional mechanical head coupled to the spindle and a separate drive unit located adjacent to the spindle within the work envelop. Power is transmitted from the drive unit to the tool via an external coupling. The second type is a mechatronic system where the drive and facing head form an integral unit. Energy and data are transmitted across an air gap by means of an induction loop. In the Heller feed-out system package, the drive unit is coupled to the facing head by means of an adjusting shaft built into the spindle. The facing head carrying the cutting tools is controlled via the U-axis--a fully functional machine axis that is programmed through the control. The rotational direction of the adjusting shaft determines the control direction of the U-axis, i.e. the direction of movement of the tool (larger or smaller diameter). As a result of the integrated design there is no collision path inside the work area, and since the tools are not equipped with a separate drive, their weight is considerably reduced. Also, the feed-out system provides another advantage that makes it superior to mechatronic solutions: the system has a significantly shorter design, resulting in a reduced tilting moment. Together with the reduced tool weight this has a positive effect on cutting performance and handling. The Heller feed-out system also provides other benefits. For example, when a facing head is placed into the spindle, the adjusting shaft integrated into the machining unit is directly coupled to the facing head. There are no uncovered interfaces. On conventional solutions these would be exposed to coolant and chips and could cause failures. And because of the fixed connection between the head and the drive through adjusting shaft, the facing head is always placed into the spindle and removed from the spindle in a known position; the position of the cutting edge is predetermined. Therefore, the facing head is always ready for immediate use without a time-wasting tryout run.

Contact Details

Related Glossary Terms

- centers

centers

Cone-shaped pins that support a workpiece by one or two ends during machining. The centers fit into holes drilled in the workpiece ends. Centers that turn with the workpiece are called “live” centers; those that do not are called “dead” centers.

- coolant

coolant

Fluid that reduces temperature buildup at the tool/workpiece interface during machining. Normally takes the form of a liquid such as soluble or chemical mixtures (semisynthetic, synthetic) but can be pressurized air or other gas. Because of water’s ability to absorb great quantities of heat, it is widely used as a coolant and vehicle for various cutting compounds, with the water-to-compound ratio varying with the machining task. See cutting fluid; semisynthetic cutting fluid; soluble-oil cutting fluid; synthetic cutting fluid.

- feed

feed

Rate of change of position of the tool as a whole, relative to the workpiece while cutting.

- machining center

machining center

CNC machine tool capable of drilling, reaming, tapping, milling and boring. Normally comes with an automatic toolchanger. See automatic toolchanger.

- turning

turning

Workpiece is held in a chuck, mounted on a face plate or secured between centers and rotated while a cutting tool, normally a single-point tool, is fed into it along its periphery or across its end or face. Takes the form of straight turning (cutting along the periphery of the workpiece); taper turning (creating a taper); step turning (turning different-size diameters on the same work); chamfering (beveling an edge or shoulder); facing (cutting on an end); turning threads (usually external but can be internal); roughing (high-volume metal removal); and finishing (final light cuts). Performed on lathes, turning centers, chucking machines, automatic screw machines and similar machines.

- turning machine

turning machine

Any machine that rotates a workpiece while feeding a cutting tool into it. See lathe.