END USER: Paragon Medical Inc., (800) 225-6975, www.paragonmedical.com.

CHALLENGE: Verify and optimize machining operations, including ensuring that cutting tools avoid interference.

SOLUTION: CNC machine simulation software.

SOLUTION PROVIDER: Spring Technologies, (617) 401-2197, www.springplm.com

A CNC machining program typically requires an additional look at the programmer’s work via simulation software to effectively verify and optimize the machining operations. Medical products manufacturer Paragon Medical Inc., Pierceton, Ind., was relying on a module in the software generating the NC code to show how the cutting tools were going to move, but wasn’t getting the whole picture.

“That software doesn’t have the model of the machine tool and never simulated the part in relationship to the machine,” said Mark Erickson, NC programmer for Paragon, a Tier 1 turnkey manufacturer of cases, trays, surgical instrumentation and implants. “We needed to see the part rotate around a 4th or 5th axis between cutting operations to make sure the tool would clear the part. Our software simulated one operation and then the next, but didn’t move the tool from point A to point B. If points A and B are on opposite ends of the part, and the retract plane is not high enough, the part might rotate into the tool. We would rather see that happen on a computer than on the machine.”

To remedy the situation, Paragon conducted an intensive 90-day software assessment. It compared evaluation copies of a couple CNC machine simulation packages and selected NCSIMUL from Spring Technologies, Cambridge, Mass. NCSIMUL simulates, verifies, optimizes and reviews machining programs for CNC machines.

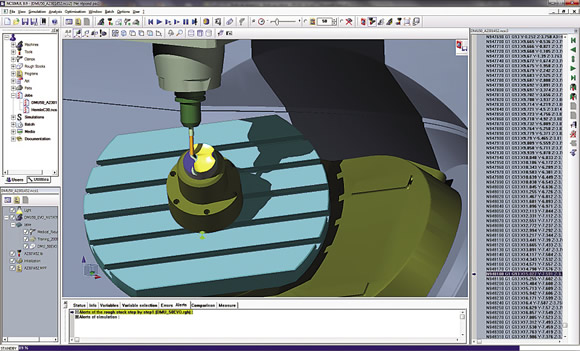

Courtesy of Spring Technologies

NCSIMUL software simulates, verifies, optimizes and reviews machining programs for CNC machines.

“We think of the simulation software as a way to check our work,” Erickson said. “It is a second set of eyes to look it over, like designers have people proofread their prints.”

Paragon chose NCSIMUL based on the graphics, according to Erickson. “I suggest that anyone looking at simulation software pick up the mouse and manipulate the results after a simulation,” he said. “Pan, rotate and, especially, zoom in on the simulation. We looked at another software package and had to wait minutes for the screen to refresh each time after zooming in to see more detail on the part.” NCSIMUL doesn’t have this delay.

Another benefit of NCSIMUL is that it finds errors automatically. The software provides a list of the errors that would have normally been caught at the machine during program execution.

“On the machine they would show up as alarms, with each one requiring us to reset the machine and restart the program until they have all been found,” Erickson said. “NCSIMUL shows all the errors at once and allows you to click on the error message to instantly find where that particular error occurred in your program. You can then correct all the problems before starting the simulation. Other simulation programs will also catch these errors; however, just like with the machine, you have to fix the error and restart the simulation again and again.”

The custom and limited-volume nature of Paragon’s products means the shop performs a lot of setups. The final decision for purchasing NCSIMUL came when Paragon realized it could save 7 to 8 hours per setup because of the documentation the software can output.

“If we can provide more information to do the setups faster, we’re looking at a good return on the software investment,” Erickson said.

According to Spring Technologies, NCSIMUL generally requires only about 2 days of training, attesting to the program’s ease of use. Also significant is the capability to demonstrate and share simulations. Downloading the NCSIMUL player application from the developer’s Web site enables customers and collaborators who don’t necessarily have licenses for the software to receive and play back NCSIMUL files and employ functionalities, such as surface measurement and finding specific G-code lines.

The extended test with the evaluation copy, Erickson said, “was a key for getting the software into Paragon. We have been talking about using simulation software for years, and we may have talked about it for many more years if we didn’t have a chance to see it firsthand. I wish all software suppliers would let you test drive their products. After all, most manufacturing software costs more than a car and you can test drive one of those.” CTE

Related Glossary Terms

- computer numerical control ( CNC)

computer numerical control ( CNC)

Microprocessor-based controller dedicated to a machine tool that permits the creation or modification of parts. Programmed numerical control activates the machine’s servos and spindle drives and controls the various machining operations. See DNC, direct numerical control; NC, numerical control.

- numerical control ( NC)

numerical control ( NC)

Any controlled equipment that allows an operator to program its movement by entering a series of coded numbers and symbols. See CNC, computer numerical control; DNC, direct numerical control.

- web

web

On a rotating tool, the portion of the tool body that joins the lands. Web is thicker at the shank end, relative to the point end, providing maximum torsional strength.