Continuing the theme of May’s column, here are additional tips for enhancing the operation of a CNC milling machine.

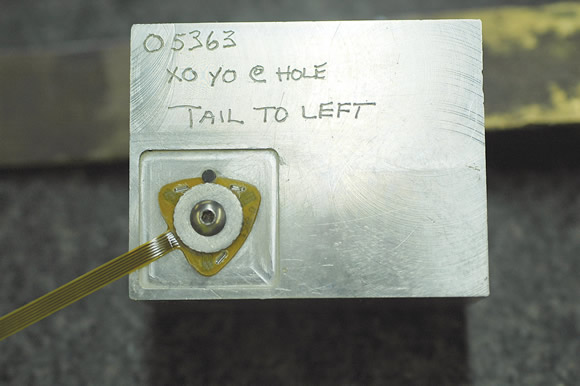

• Permanently engrave important offset and program information directly into your soft jaws. Then you’re not trying to figure it out in 6 months when the job repeats. Extra information available at the machine during setup reduces mistakes and increases setup speed and confidence.

• Cut a pickup feature or features directly into your fixtures and soft jaws. There’s nothing like a good round hole marked X0/Y0 to set up from the next time you use a fixture.

Engrave important program and offset information directly into fixtures and soft jaws.

• I’ve never had to do it yet, but I have heard about somebody doing a job that was a couple of inches outside the X-axis travel of the machine. The job requirements were such that it was best to do it in one setup. The solution was to align the part’s X-axis diagonally with the machine axis. This put the part axis on the hypotenuse of the machine’s X- and Y-axis travels and provided the extra couple of inches needed to do the job. With modern CAM systems, this is a viable option.

• A silver metallic felt pen provides a quick, easy way to mark a tool offset directly on a black-oxide toolholder. It only takes a second to record an offset and it’s cheaper than tags. Heck, I can’t even buy the nifty little tags for my BT-35 holders, so I improvise like a true cheapskate.

A silver metallic felt pen provides a quick, easy way to mark a tool offset directly on a black-oxide toolholder.

• Engraving is super sensitive to cutting depth. Your engraving will look lousy if the surface is sloped, dished or not where you think it is. The best approach is to establish an accurately known Z position just prior to the engraving operation. An alternative is to cut a shallow pocket for the engraving to reside in. The pocket also helps protect the engraving from damage because it is recessed.

• You can use an M00 or M01 command just prior to a tapping cycle when threading difficult-to-cut materials. Manually dab a little heavy-duty tapping fluid directly on the tap. (Water-based coolants leave something to be desired for tough tapping operations.) M00 is the preferred method because the default machine condition is a safe one, unlike the optional stop where the operator must remember to have a switch set.

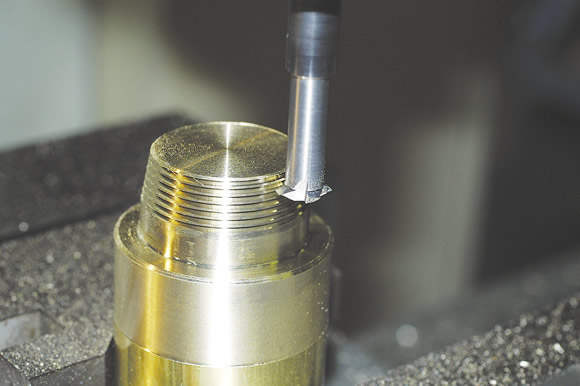

In addition to milling common thread pitches, a single-flute thread mill can mill those oddball thread pitches that come up every once in a while.

• If you haven’t tried thread milling, you should. Sometimes it’s the only way to thread a delicate part. When thread milling, the cutting forces are low and it’s easy to adjust the thread-pitch diameter for a perfect gage fit. You can also cut a full-engagement pipe thread with less than the full depth of hole you would otherwise need, even with a short projection pipe tap.

• Don’t stress too much about ramp-in and ramp-out moves if you are manually programming thread milling. The straight-in approach works fine and is easier to think about than ramping moves the first few times you try it. Most of the time, you are ramping into air or a thread relief. You can use G41/G42 tool compensation if you like to adjust the diameter, but this can be a little tricky to do down the hole of an internal thread. I generally do the entire thread without tool compensation and adjust the X or Y point where the tool starts to orbit for the helix. I put a marker in the program so I can find it easily. With a single-flute thread mill, you can also mill those oddball thread pitches that come up every once in a while.

A great way to clean collets is in an ultrasonic cleaner.

• I’m sure everybody has experienced the weird phenomena of an endmill or drill lasting for hundreds of parts and then, after replacing the tool “just in case,” having the new tool last for only one part. Check a few of your ER-style collet setups for runout when that happens. You might be shocked at what you find. These collets are not automatically accurate. This is particularly important with small tools that cannot tolerate much runout in proportion to their diameters. If you find runout, thoroughly clean the collet and holder. The culprit is usually the inside surface of the nut and collets, which have coolant residue or small burrs on them where the nut contacts the collet.

• A great way to clean collets is in an ultrasonic cleaner. Small chips and debris worm their way into the collet slits and ruin accuracy. Use a heated solution of degreaser, such as Simple Green or Omni-All, followed by drying and dipping in lightweight oil, such as M-1 or WD-40. CTE

About the Author: Tom Lipton is a career metalworker who has worked at various job shops. He has received six U.S. patents and lives in Alamo, Calif., For more information, visit his blog at oxtool.blogspot.com and video channel at www.youtube.com/user/oxtoolco. Lipton’s column is adapted from information in his book “Metalworking Sink or Swim: Tips and Tricks for Machinists, Welders, and Fabricators,” published by Industrial Press Inc., New York. The publisher can be reached by calling (888) 528-7852 or visiting www.industrialpress.com. By indicating the code CTE-2013 when ordering, CTE readers will receive a 20 percent discount off the book’s list price of $44.95.Related Glossary Terms

- collet

collet

Flexible-sided device that secures a tool or workpiece. Similar in function to a chuck, but can accommodate only a narrow size range. Typically provides greater gripping force and precision than a chuck. See chuck.

- computer numerical control ( CNC)

computer numerical control ( CNC)

Microprocessor-based controller dedicated to a machine tool that permits the creation or modification of parts. Programmed numerical control activates the machine’s servos and spindle drives and controls the various machining operations. See DNC, direct numerical control; NC, numerical control.

- computer-aided manufacturing ( CAM)

computer-aided manufacturing ( CAM)

Use of computers to control machining and manufacturing processes.

- coolant

coolant

Fluid that reduces temperature buildup at the tool/workpiece interface during machining. Normally takes the form of a liquid such as soluble or chemical mixtures (semisynthetic, synthetic) but can be pressurized air or other gas. Because of water’s ability to absorb great quantities of heat, it is widely used as a coolant and vehicle for various cutting compounds, with the water-to-compound ratio varying with the machining task. See cutting fluid; semisynthetic cutting fluid; soluble-oil cutting fluid; synthetic cutting fluid.

- endmill

endmill

Milling cutter held by its shank that cuts on its periphery and, if so configured, on its free end. Takes a variety of shapes (single- and double-end, roughing, ballnose and cup-end) and sizes (stub, medium, long and extra-long). Also comes with differing numbers of flutes.

- fixture

fixture

Device, often made in-house, that holds a specific workpiece. See jig; modular fixturing.

- gang cutting ( milling)

gang cutting ( milling)

Machining with several cutters mounted on a single arbor, generally for simultaneous cutting.

- milling

milling

Machining operation in which metal or other material is removed by applying power to a rotating cutter. In vertical milling, the cutting tool is mounted vertically on the spindle. In horizontal milling, the cutting tool is mounted horizontally, either directly on the spindle or on an arbor. Horizontal milling is further broken down into conventional milling, where the cutter rotates opposite the direction of feed, or “up” into the workpiece; and climb milling, where the cutter rotates in the direction of feed, or “down” into the workpiece. Milling operations include plane or surface milling, endmilling, facemilling, angle milling, form milling and profiling.

- milling machine ( mill)

milling machine ( mill)

Runs endmills and arbor-mounted milling cutters. Features include a head with a spindle that drives the cutters; a column, knee and table that provide motion in the three Cartesian axes; and a base that supports the components and houses the cutting-fluid pump and reservoir. The work is mounted on the table and fed into the rotating cutter or endmill to accomplish the milling steps; vertical milling machines also feed endmills into the work by means of a spindle-mounted quill. Models range from small manual machines to big bed-type and duplex mills. All take one of three basic forms: vertical, horizontal or convertible horizontal/vertical. Vertical machines may be knee-type (the table is mounted on a knee that can be elevated) or bed-type (the table is securely supported and only moves horizontally). In general, horizontal machines are bigger and more powerful, while vertical machines are lighter but more versatile and easier to set up and operate.

- milling machine ( mill)2

milling machine ( mill)

Runs endmills and arbor-mounted milling cutters. Features include a head with a spindle that drives the cutters; a column, knee and table that provide motion in the three Cartesian axes; and a base that supports the components and houses the cutting-fluid pump and reservoir. The work is mounted on the table and fed into the rotating cutter or endmill to accomplish the milling steps; vertical milling machines also feed endmills into the work by means of a spindle-mounted quill. Models range from small manual machines to big bed-type and duplex mills. All take one of three basic forms: vertical, horizontal or convertible horizontal/vertical. Vertical machines may be knee-type (the table is mounted on a knee that can be elevated) or bed-type (the table is securely supported and only moves horizontally). In general, horizontal machines are bigger and more powerful, while vertical machines are lighter but more versatile and easier to set up and operate.

- relief

relief

Space provided behind the cutting edges to prevent rubbing. Sometimes called primary relief. Secondary relief provides additional space behind primary relief. Relief on end teeth is axial relief; relief on side teeth is peripheral relief.

- tap

tap

Cylindrical tool that cuts internal threads and has flutes to remove chips and carry tapping fluid to the point of cut. Normally used on a drill press or tapping machine but also may be operated manually. See tapping.

- tapping

tapping

Machining operation in which a tap, with teeth on its periphery, cuts internal threads in a predrilled hole having a smaller diameter than the tap diameter. Threads are formed by a combined rotary and axial-relative motion between tap and workpiece. See tap.

- threading

threading

Process of both external (e.g., thread milling) and internal (e.g., tapping, thread milling) cutting, turning and rolling of threads into particular material. Standardized specifications are available to determine the desired results of the threading process. Numerous thread-series designations are written for specific applications. Threading often is performed on a lathe. Specifications such as thread height are critical in determining the strength of the threads. The material used is taken into consideration in determining the expected results of any particular application for that threaded piece. In external threading, a calculated depth is required as well as a particular angle to the cut. To perform internal threading, the exact diameter to bore the hole is critical before threading. The threads are distinguished from one another by the amount of tolerance and/or allowance that is specified. See turning.

- toolholder

toolholder

Secures a cutting tool during a machining operation. Basic types include block, cartridge, chuck, collet, fixed, modular, quick-change and rotating.