I am surprised by the number of engineers and machinists who are not familiar with traditional machining tools and techniques. Many metalworking professionals seem to default to using only sophisticated technology for all aspects of machining without understanding or being able to use more traditional options. This habit includes using coordinate measuring machines to measure parts that can be measured with hand tools, replacing edge finders and indicators with machine tool probes and relying on CAM and conversational programming instead of manually calculating the coordinates of holes in a bolt circle.

Before becoming a manufacturing engineer, I ran a family-owned machine shop. My first machining experiences were on lathes built in the 1940s and knee mills from the 1960s—none of which had digital readouts, power feeds or any of the other now common time-saving accessories. I learned “old school” machining by running manual machines for several years before being introduced to CNC equipment. The skills I learned on those manual machines have been more beneficial than any other training or education I have received, and I exploit every opportunity to practice them.

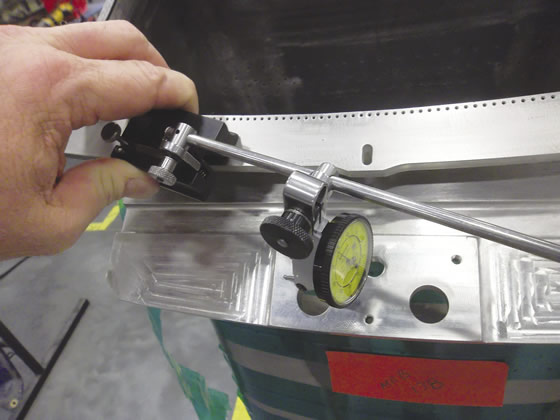

The author uses this surface gage—one of his favorite tools—to inspect a machined face for flatness.

When I’m at work, I keep my dark-walnut Gerstner toolbox by my desk so my tools are readily available. Why? Because those simple tools are invaluable. Every machinist and manufacturing engineer should have a few common tools at every job. The following are some of them.

Machinery’s Handbook from Industrial Press Inc. is so important that many toolbox manufacturers include a drawer specifically designed to house it. The master toolmaker I learned from told me to buy it before anything else. I have three of the 29 editions and the oldest one has pages marked for quick reference. I can find information faster in this book than I can find it online.

The second tool the master toolmaker told me to buy is a surface gage. I don’t often see surface gages in “young guy” toolboxes, which is unfortunate. In the world of CNC and CMM, many machinists and toolmakers no longer perform proper layout, which is the primary function of a surface gage. However, like test indicators, they have limitless uses. I have used them to prove the flatness of machined surfaces and paired one with an indicator to measure part height on a surface grinder chuck. You can hold the V-groove against a shaft and verify concentricity to a bearing race, and, by resting the pins against the edge of a mill table, you can align long parts or vise jaws without having to crank the mill handles. It is also possible to check the alignment of machine ways with a surface gage and an indicator.

A battery-powered calculator (solar ones don’t always work well under shop light) is also indispensable for machining. I have a $15 scientific calculator to access trigonometry functions. One without those functions works, but you will have to open the Machinery’s Handbook to find, for example, the sine of 29° and 15 minutes.

The same surface gage is also suitable for inspecting the parallelism of two machined faces.

In addition, I always have an edge finder. I prefer the single-ended model with a 0.200 " diameter because I can put it in more places than the double-ended version. Of course, the tool’s typical function is to find the corner or edge of a part, but it can also find the center of a hole, usually to within 0.001 ". I have also used them, along with DROs, to measure parts on knee mills. They are rugged and never need batteries.

I also recommend a test indicator, which measures small changes in distance, with accessories for attaching to height gages, machine tools and magnetic bases. I have collected several over the years, but I prefer the one that has 0.030 " of travel and is graduated in thousandths of an inch.

The test indicator should have a medium-sized magnetic base with solid rods. A magnetic base makes the possible uses of a test indicator almost limitless. I prefer not to have fine adjustment on the base, because the fragile nature of the fine-adjustment feature is subject to error from the indicator’s weight when held upside down. Compared to ones with solid rods, newer magnetic bases with flexible necks don’t seem to hold up over time and have moving parts that can disappear.

A matched set of one-two-three blocks (or several sets if you can afford them) is invaluable as well. A one-two-three block has dimensions measuring 1 ", 2 " and 3 " long, respectively. Typically, most people use the blocks as parallels on a mill or granite plate—the intended purpose—but they can be combined with a magnetic base and test indicator to make an impromptu surface gage. And by wrapping a piece of Emory paper around one, you have a lapping tool to help restore surface flatness. You can make your own one-two-three blocks and, by drilling holes to match the major diameter of different taps, create a tapping block that helps get a hand tap started straight.

Medium-sized, matched V-blocks are always useful and well worth the money. They are jigs typically used to hold round workpieces for measurement or machining. One of my favorite uses is to put one against a stationary jaw, with the V-groove facing the moving jaw and the side of the V-block on the bottom of the vise. This arrangement forces the shaft parallel and square to the mill spindle, and can be done so the shaft is held horizontally or vertically.

Several other tools, such as micrometers, calipers, scales and squares, are important as well, although they don’t have the same versatility as the previously mentioned tools. Those simple—albeit expensive—tools will always have machining applications. I suspect most “old shop guys” have them and use them regularly.

Demonstrating the tool’s versatility, a surface gage can also check the alignment of a part relative to the machine table.

I fully embrace the technology found in the modern metalworking facility and employ it every day. However, there is a growing population of machinists and engineers who struggle with problems that cannot be solved immediately with newer technology. I see problems with CMM measurements and machine setups that can be easily and quickly solved with these “old tools,” but the people who understand how to use them are becoming increasingly rare. Please e-mail me your novel “tips and tricks” for using simple tools. I’d love to include them in a column. CTE

About the Author: Christopher Tate is senior advanced manufacturing manager for Milwaukee Electric Tool Corp., Brookfield, Wis. He is based at the company’s manufacturing plant in Jackson, Miss. Tate has 19 years of experience in the metalworking industry and holds a Master of Science and Bachelor of Science from Mississippi State University. E-mail: [email protected].Related Glossary Terms

- V-block

V-block

Workholding device with V-shaped slot for holding pipe and other round stock during machining or inspection.

- chuck

chuck

Workholding device that affixes to a mill, lathe or drill-press spindle. It holds a tool or workpiece by one end, allowing it to be rotated. May also be fitted to the machine table to hold a workpiece. Two or more adjustable jaws actually hold the tool or part. May be actuated manually, pneumatically, hydraulically or electrically. See collet.

- computer numerical control ( CNC)

computer numerical control ( CNC)

Microprocessor-based controller dedicated to a machine tool that permits the creation or modification of parts. Programmed numerical control activates the machine’s servos and spindle drives and controls the various machining operations. See DNC, direct numerical control; NC, numerical control.

- computer-aided manufacturing ( CAM)

computer-aided manufacturing ( CAM)

Use of computers to control machining and manufacturing processes.

- conversational programming

conversational programming

Method for using plain English to produce G-code file without knowing G-code in order to program CNC machines.

- edge finder

edge finder

Gage mounted in the spindle of a vertical mill and used, while rotating, to find the center of a part relative to the toolholder.

- lapping

lapping

Finishing operation in which a loose, fine-grain abrasive in a liquid medium abrades material. Extremely accurate process that corrects minor shape imperfections, refines surface finishes and produces a close fit between mating surfaces.

- metalworking

metalworking

Any manufacturing process in which metal is processed or machined such that the workpiece is given a new shape. Broadly defined, the term includes processes such as design and layout, heat-treating, material handling and inspection.

- milling machine ( mill)

milling machine ( mill)

Runs endmills and arbor-mounted milling cutters. Features include a head with a spindle that drives the cutters; a column, knee and table that provide motion in the three Cartesian axes; and a base that supports the components and houses the cutting-fluid pump and reservoir. The work is mounted on the table and fed into the rotating cutter or endmill to accomplish the milling steps; vertical milling machines also feed endmills into the work by means of a spindle-mounted quill. Models range from small manual machines to big bed-type and duplex mills. All take one of three basic forms: vertical, horizontal or convertible horizontal/vertical. Vertical machines may be knee-type (the table is mounted on a knee that can be elevated) or bed-type (the table is securely supported and only moves horizontally). In general, horizontal machines are bigger and more powerful, while vertical machines are lighter but more versatile and easier to set up and operate.

- parallel

parallel

Strip or block of precision-ground stock used to elevate a workpiece, while keeping it parallel to the worktable, to prevent cutter/table contact.

- tap

tap

Cylindrical tool that cuts internal threads and has flutes to remove chips and carry tapping fluid to the point of cut. Normally used on a drill press or tapping machine but also may be operated manually. See tapping.

- tapping

tapping

Machining operation in which a tap, with teeth on its periphery, cuts internal threads in a predrilled hole having a smaller diameter than the tap diameter. Threads are formed by a combined rotary and axial-relative motion between tap and workpiece. See tap.