END USER: PMC-Colinet, (800) 451-1306, www.pmc-colinet.com.

CHALLENGE: Boost productivity when machining keyways into a Nitralloy steel cutting tool head.

SOLUTION: Switch the work to a vertical machining center and obtain a custom 90° angle head.

SOLUTION PROVIDER: Heimatec Inc., (847) 749-0633, www.heimatecinc.com.

Founded in 1912, PMC-Colinet, Wickliffe, Ohio, is a builder of machines for the oil-country-tubular-goods sector. The company’s customers include integrated steel mills that sell finished pipe and couplings to the oil and gas industries. The mills use the machines to thread products for down-hole drilling. PMC-Colinet also supplies cutting tools, consumable tooling and aftermarket parts and provides field service.

One particularly challenging job requires cutting keyways into a large section on a cutting tool head made of Nitralloy steel. For many years, PMC-Colinet used a shaping machine to produce the keyways in the bores of die heads. Typically, the bores range from 6 " (152.4mm) to 13 " (330.2mm) in diameter and more than 12 " (304.8mm) in length. The keyway tolerances are tight, with location at ±0.0005 " (0.013mm), width at ±0.001 " (0.025mm) and depth at ±0.0025 " (0.064mm).

One style of cut is a three-step keyway that does not run all the way through the bore, stopping instead at a window milled from the part’s OD. This situation posed two options. One required PMC to rough the keyway on the shaper, then outsource the part for finishing with a sinker EDM because PMC doesn’t have that type of machine. This process consumed 50 hours on the shaper, plus about a week for the EDM work.

Another option was to do the job entirely on the shaping machine. Roughing the keyway required about 61 hours. Finishing consumed another 145 hours. The roughing and finishing times included 10 to 12 hours for setup.

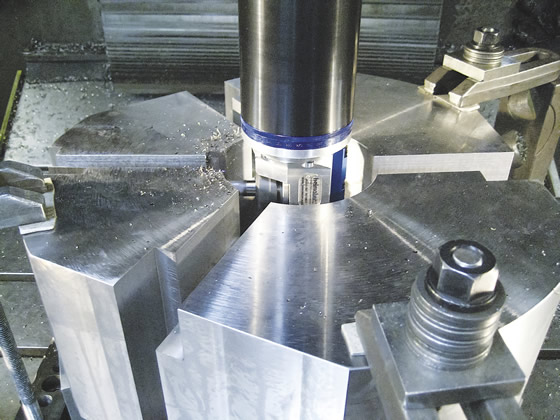

Heimatec designed this special 16 "-long, 90° angle head for cutting the keyway in a cutting tool head used in the oil field industry.

Milling Foreman Rick Kokish said PMC used both options, depending on which method could get the job done the quickest. “We had one vendor we used who had a large enough EDM to handle our larger heads. We were pretty much at their mercy as to when they could get a head on the machine based on their work load.”

The team at PMC decided to explore methods to increase productivity by producing the part on its Monarch 175B vertical machining center. However, doing so required a 90° angle head to cut a keyway with sharp corners in a bore as small as 6.00 " in diameter that is parallel to the keyway, so the team conducted an exhaustive Internet search. After more than 30 hours of weeding out unsuitable products, two vendors remained. “First, we eliminated heads by size,” Kokish said. “If the angle head could only do one or two different sizes, it would not be a great fit for us.”

He added that price was also a factor—but not from a budgetary standpoint. “If the cost was very low, we felt we would probably suffer on quality.”

The two angle-head manufacturers visited PMC’s facility and brought their standard designs. One of the qualifiers, Heimatec Inc., Prospect Heights, Ill., quickly realized the job required a custom 90° head design to meet all requirements. For example, none of its standard heads were suitable for producing the keyway in the smallest-diameter cutting tool head, Kokish noted.

Heimatec also gained an edge by presenting a larger, heavier unit for a 50-taper machine, while the competition brought a 40-taper design. “Our die heads are just too large to go on any of our 40-taper machines,” Kokish said. “And the rigidity needed for close tolerances and accuracy would most likely be provided with a 50-taper machine tool.”

PMC-Colinet applies a custom 90° angle head from Heimatec on a Monarch vertical machining center to produce keyways in the bore on an oil field pipe, typically 6 " to 13 " in diameter and 12 " in length.

A week later, Heimatec President Preben Hansen supplied a drawing for the proposed custom product. After reviewing the standard and custom designs from both companies, PMC awarded the project to Heimatec. From conception to installation, the project took about 7 months.

Although the custom angle head for radial drilling and milling is suitable for use in producing various products at PMC, Kokish said the company only uses it for machining keyways in die heads. “We do not want to risk damaging the 90° head with unnecessary abuse on other applications.”

In one angle-head application for a keyway in a bore 6 " (152.4mm) in diameter and 12 " (304.8mm) long, PMC spent 6 hours on setup, equally divided between roughing and finishing, and 12 to 16 hours on machining. This saved PMC at least 184 hours on a single part compared to doing the job entirely on the shaping machine.

The design for the custom head includes an adjustable tool stop, three support pins for stabilizing the tool, a 360° indexable pivot on the angle head and an inclined tooth gear to enhance rigidity. Initially, the angle head, which is 3.897 " (99mm) in diameter and 12.795 " (325mm) long, appeared too slender to provide the required rigidity throughout the entire cutting cycle, according to Kokish. “It just seemed it would chatter and vibrate,” he said.

However, those fears proved unjustified. PMC only experienced one vibration problem when a support pin became loose. Otherwise, the company deemed the performance successful.

Related Glossary Terms

- chatter

chatter

Condition of vibration involving the machine, workpiece and cutting tool. Once this condition arises, it is often self-sustaining until the problem is corrected. Chatter can be identified when lines or grooves appear at regular intervals in the workpiece. These lines or grooves are caused by the teeth of the cutter as they vibrate in and out of the workpiece and their spacing depends on the frequency of vibration.

- electrical-discharge machining ( EDM)

electrical-discharge machining ( EDM)

Process that vaporizes conductive materials by controlled application of pulsed electrical current that flows between a workpiece and electrode (tool) in a dielectric fluid. Permits machining shapes to tight accuracies without the internal stresses conventional machining often generates. Useful in diemaking.

- gang cutting ( milling)

gang cutting ( milling)

Machining with several cutters mounted on a single arbor, generally for simultaneous cutting.

- machining center

machining center

CNC machine tool capable of drilling, reaming, tapping, milling and boring. Normally comes with an automatic toolchanger. See automatic toolchanger.

- milling

milling

Machining operation in which metal or other material is removed by applying power to a rotating cutter. In vertical milling, the cutting tool is mounted vertically on the spindle. In horizontal milling, the cutting tool is mounted horizontally, either directly on the spindle or on an arbor. Horizontal milling is further broken down into conventional milling, where the cutter rotates opposite the direction of feed, or “up” into the workpiece; and climb milling, where the cutter rotates in the direction of feed, or “down” into the workpiece. Milling operations include plane or surface milling, endmilling, facemilling, angle milling, form milling and profiling.

- outer diameter ( OD)

outer diameter ( OD)

Dimension that defines the exterior diameter of a cylindrical or round part. See ID, inner diameter.

- parallel

parallel

Strip or block of precision-ground stock used to elevate a workpiece, while keeping it parallel to the worktable, to prevent cutter/table contact.

- shaping

shaping

Using a shaper primarily to produce flat surfaces in horizontal, vertical or angular planes. It can also include the machining of curved surfaces, helixes, serrations and special work involving odd and irregular shapes. Often used for prototype or short-run manufacturing to eliminate the need for expensive special tooling or processes.

- slotting machine ( shaper)

slotting machine ( shaper)

Vertical or horizontal machine that accommodates single-point, reciprocating cutting tools to shape or slot a workpiece. Normally used for special (unusual/intricate shapes), low-volume runs typically performed by broaching or milling machines. See broaching machine; mill, milling machine.