END USER: Cobham Electronic Systems Inc., (978) 442-4700, www.cobham.com.

CHALLENGE: Reduce costs associated with inventory management.

SOLUTION: An industrial vending system.

SOLUTION PROVIDER: MSC Industrial Supply Co., (800) 645-7270, www.mscdirect.com.

Cobham Electronic Systems Inc., Lowell, Mass., needed to streamline its inventory management system. The manufacturer’s massive storeroom—and the huge number of requisitions, purchase orders and invoices it generated—was costing the company time and money. Purchasing Manager Norm Cheever knew there had to be a better way.

“We were looking for a mechanism to control that and take the extensive workload away from not only purchasing, but from requisitions, receiving and accounting as well,” Cheever said. “I’d had experience with vending-type machines in other businesses I’ve worked at, so I knew their potential.”

Because Cobham had an existing supply contract with MSC Industrial Supply Co., Melville, N.Y., the company decided to expand that contract to cover MSC’s ControlPoint inventory vending and procurement system.

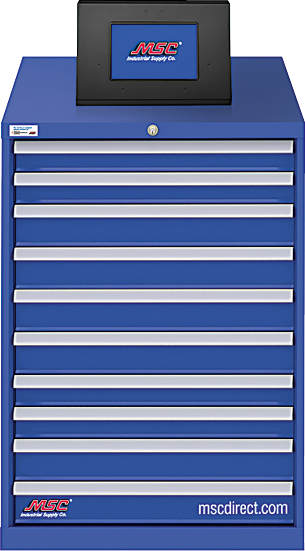

The electronically controlled tool cabinet is available with or without an on-machine control tablet.

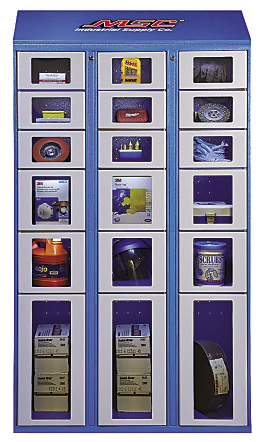

MSC’s modular lockers can accommodate a range of items, including large and heavy ones.

“Our previous system involved a huge storeroom and one person writing invoices, purchase orders and requisition forms for everything,” Cheever said. “It worked, but was time-consuming and costly.”

In 2010, Cobham installed its first two machines, dispensing cutting tools in the shop’s CNC area. Today, six machines are positioned throughout the plant, with plans to add a seventh unit and possibly even more, if business keeps growing as projected, Cheever said.

Cobham uses a hybrid approach to inventory management. Cobham owns the consumable material, but MSC stocks the machines.

“We also use e-procurement as much as we can, which saves us time and allows us to combine purchase orders rather than having a bunch of individual orders, which makes it easier for receiving,” Cheever explained. “And our accounting department, while they haven’t quantified it, are thrilled that the number of invoices they have to process for MSC has dropped dramatically.”

Because ControlPoint is a just-in-time inventory management system with supplies replenished daily, it helps Cobham minimize the on-hand stock it needs. In addition to reducing storage space, the system helps minimize the effort required to maintain shop inventory.

“If I look at the number of purchase orders we used to generate compared to what simply goes through the vending system today, we have saved the equivalent of a full-time employee’s salary,” Cheever said.

“We have visitors come in from other businesses to check out what we have implemented,” he continued. “The savings that we’ve seen, between receiving, accounting, procurement and inventory management, have all gotten attention. When I talk to people who are doing things the old way, it just boggles my mind that anyone would not have taken advantage of a system that brings the kind of positive changes we’ve seen.”

In addition to cost savings, ControlPoint provides requisition data in whatever format is most useful. For example, data can be viewed by machine to see which department is using the most materials or by how much each individual operator uses.

However, there is an alternative for companies that might not always use this monitoring capability. “What we find is that, although this technology is out there in their shops, customers tend not to leverage the reporting capability, which is where MSC’s consultants come in,” said Gary Garrity, MSC’s national accounts manager. “They can interpret that data for the customer and point out potential areas to focus on. The cooperative relationship between the customer and the vendor is paramount.”

Related Glossary Terms

- computer numerical control ( CNC)

computer numerical control ( CNC)

Microprocessor-based controller dedicated to a machine tool that permits the creation or modification of parts. Programmed numerical control activates the machine’s servos and spindle drives and controls the various machining operations. See DNC, direct numerical control; NC, numerical control.

- just-in-time ( JIT)

just-in-time ( JIT)

Philosophy based on identifying, then removing, impediments to productivity. Applies to machining processes, inventory control, rejects, changeover time and other elements affecting production.

- payload ( workload)

payload ( workload)

Maximum load that the robot can handle safely.