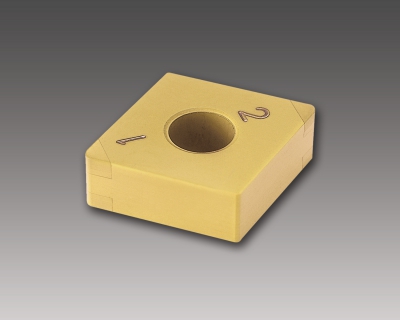

Sumitomo’s new BNC2000 series CBN grades perform with exceptional accuracy and productivity. The BNC2010 grade is designed for high precision hard turning. A newly developed CBN substrate coated with a TiCN layer achieves excellent surface finish, while reducing wear.

The high efficiency BNC2020 Grade is designed for general hardened steel machining. Featuring a newly developed tough CBN substrate coated with a highly wear-resistant TiAlN layer it achieves more stable machining and a longer tool life.

Contact Details

Related Glossary Terms

- cubic boron nitride ( CBN)

cubic boron nitride ( CBN)

Crystal manufactured from boron nitride under high pressure and temperature. Used to cut hard-to-machine ferrous and nickel-base materials up to 70 HRC. Second hardest material after diamond. See superabrasive tools.

- hard turning

hard turning

Single-point cutting of a workpiece that has a hardness value higher than 45 HRC.

- titanium aluminum nitride ( TiAlN)

titanium aluminum nitride ( TiAlN)

Often used as a tool coating. AlTiN indicates the aluminum content is greater than the titanium. See coated tools.

- titanium carbonitride ( TiCN)

titanium carbonitride ( TiCN)

Often used as a tool coating. See coated tools.

- turning

turning

Workpiece is held in a chuck, mounted on a face plate or secured between centers and rotated while a cutting tool, normally a single-point tool, is fed into it along its periphery or across its end or face. Takes the form of straight turning (cutting along the periphery of the workpiece); taper turning (creating a taper); step turning (turning different-size diameters on the same work); chamfering (beveling an edge or shoulder); facing (cutting on an end); turning threads (usually external but can be internal); roughing (high-volume metal removal); and finishing (final light cuts). Performed on lathes, turning centers, chucking machines, automatic screw machines and similar machines.