To compete, high-mix, low-volume parts manufacturers are well-aware that they need to spend as much time as possible in the cut rather than setting up. Chucks with quick-change jaws let them do just that.

In addition, quick-change jaws help shops overcome the skills gap, according to Steve Hartung, group product manager for rotational workholding at SCHUNK Inc., Morrisville, N.C. Shops can easily train less-skilled operators to quickly and accurately change a chuck’s soft jaws, also known as top tooling or inserts, via a simple-to-use tool and, in many cases, avoid having to rebore the jaws.

For example, Hartung said the SCHUNK PRONTO quick-change-jaw system (shown) only requires an operator to turn a T-wrench 90° to remove an insert and turn another 90° in the opposite direction to install a new insert for a new job. The process consumes about 5 seconds per jaw and provides a repeatability of 25µm (0.00098"). And to further enhance productivity, a robot can easily be programmed to swap the PRONTO inserts.

“That’s another advantage of the system,” he said.

Saving Time and Money

Moreover, reducing the time it takes to change the workholding setup on a chuck from one job to the next provides a fast return on investment for a quick-change chuck jaw, which has a higher acquisition cost than a standard soft top jaw.

A quick-change-jaw chuck with fixture from Pratt Burnerd America. Image courtesy of Pratt Burnerd America.

Lee Chase, CEO of QCS Workholding LLC, Houston, said the nominal setup time for a proficient worker to change standard jaws is 15 to 20 minutes. The process typically involves breaking the bolts, finding the required jaws, removing the jaws from the previous job and replacing them with the ones for the new job. “And usually, for accuracy, you’re going to have to rebore them,” he added.

Chase knows the process well because he ran a lathe when the company started as a job shop. “About the fourth time we changed our standard jaws in a day, I said, ‘There’s got to be a better way,’” Chase recalled. “The next day, the owner had the first prototype made.”

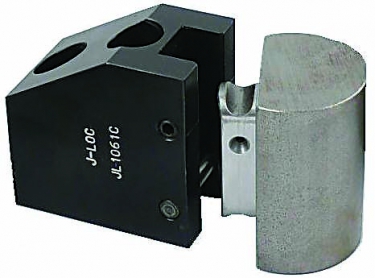

In contrast to changing standard jaws, a jaw change takes 10 seconds with QCS’ J-LOC quick-change chuck jaw when the master jaws are on a chuck, Chase said. To show the cost savings that the reduced setup time can achieve, the company provides a cost comparison between standard soft jaws and J-LOC C-style quick-change jaws mounted on a 10" (254mm) 3-jaw Kitagawa chuck. (Visit tinyurl.com/ydz8auww.) The comparison shows the cost of acquiring 10 sets of standard soft jaws ($630) versus one set of J-LOC quick-change chuck jaws ($780) and 10 sets of J-LOC quick-change inserts ($1,350), or $1,500 more.

However, according to the company, the estimated cost for 10 repeated usages of 10 sets of standard soft jaws is $5,630 compared with the estimated cost of $2,737 for 10 repeated usages of 10 sets of the quick-change inserts—a savings of $2,893.

Chase explained that the company’s inserts, which are made of mild steel, are bored like soft jaws. After a shop initially bores the inserts, they are placed back on the master jaws for repeat jobs, the program is changed and the job is run. To achieve a repeatability of 0.0005" (12.7µm), an insert must be placed back on the same master jaw it was bored on, which requires properly numbering the master jaws and their inserts.

A J-LOC C-style quick-change chuck jaw from QCS Workholding. Image courtesy of QCS Workholding.

“You just take your standard jaws off and replace them with our master jaws,” Chase said. “Theoretically, you don’t ever want to remove the master jaws once you bolt them on. All your adaptation is done with the inserts.”

To make the inserts more economical, they are reversible, he added. “You can bore each end of a set of inserts for a different diameter.”

Force Factor

It’s important that the chuck maintains as much jaw force as possible at the lathe’s maximum speed.

According to B.J. Lillibridge, vice president of Pratt Burnerd America, Kalamazoo, Mich., a typical wedge-style power chuck loses more than 60 percent of its jaw force at maximum rpm because centrifugal force causes the jaws to pull away from the part. To provide a higher gripping force, PBA offers a chuck with a lever-wedge design for its quick-change chuck jaw system.

The wedge moves the actuator block, which also functions as a counterweight, Lillibridge said. As a result, the chuck is counterbalanced for speeds up to 6,000 rpm and will typically maintain 80 to 90 percent of its jaw force at the top speed. He added that because PBA’s quick-change-jaw chuck is counterbalanced, customers can use full-size master jaws and, therefore, their existing top tooling.

The PBI GripSafe grip meter from Pratt Burnerd America measures static and dynamic gripping forces. Image courtesy of Greg Bartlett.

Maintaining a high percentage of a chuck’s jaw force is particularly advantageous when turning thin-wall components. In those applications, an end user reduces the force on a part to prevent its walls from being distorted, Lillibridge noted. If a chuck loses a significant portion of its gripping capability after the clamping force was already reduced, the part might come out of the jaws during machining.

“You could turn the pressure down so you don’t crush the part,” he said about PBA’s chuck, “but still maintain the force with the counterbalance. It’s much safer because of that.”

In addition, the power chuck can perform collet work, Lillibridge said. “With our chuck, you put Warner & Swasey-type collet pads in the master jaws, and you don’t use top jaws.”

To further enhance safety, PBA introduced the PBI GripSafe grip meter. The meter is suitable for measuring the static and dynamic gripping force of any 2- or 3-jaw chuck at up to 6,000 rpm, the company reports.

“You could see how much jaw force you lose as the speed increases,” Lillibridge said, adding that the heavier the jaw, the greater the force loss. “You grip the load cell, and it sends out a Wi-Fi signal. You download the app and check the jaw force on your cellphone.”

Dialogue and Diligence

Before recommending a quick-change-jaw system—or a quick-change anything, for that matter—Hartung emphasized the importance of understanding a customer’s needs. “Do our customers need quick change or to run more product or do faster changeovers or have more flexibility?” he asked. “That’s the question we need to answer while discussing their process-improvement requirements. Then we apply the product, and quick change is the answer in many situations.”

While machine tool builders have made strides with respect to turning center technology, such as providing mill-turn capability, more axes, quick-change tooling on turrets and enhanced tool magazines, Hartung said one component generally remains a constant. “The same chuck that comes on one of these machines that can do all these crazy and cool things today is no different than the one that came on a 3-axis lathe 30 years ago.”

The ROTA quick-change-jaw system from SCHUNK can be combined with multiple top jaws to allow many types of ID and OD clamping. Image courtesy of SCHUNK.

The machine comes with a general-purpose chuck because the builder doesn’t know what the end user’s application is, he explained. “To be honest, it would be better for a lathe to come in like a mill does. What does the mill come in with on the table? Nothing, because they don’t know what the machine is going to do.”

Lillibridge, however, said machine builders equip new lathes with a standard chuck because it costs 30 to 40 percent less than a chuck with quick-change jaws, and builders want to keep the base price down. “So those machines will come with a standard chuck unless the customer says, ‘I read about these quick-change-jaw chucks, and that’s what I want.’”

Nonetheless, times are changing, and Hartung said machine builders and dealers are starting to more thoroughly examine the accessory side, such as workholding devices, particularly for high-end, high-performance machines. “If your workholding doesn’t perform like the machine does, you’re really not providing the solution tailored to the customer’s needs.”

Another change he would like to see is for someone to coin a different term for “quick change.” “We’ve used it for so long that it’s almost falling on deaf ears,” Hartung said. “We’re really not paying attention to it. But today, we need to focus on productivity more than ever.”

A change to that entry in machining’s lexicon, however, is unlikely to be quick.

Contact Details

Contact Details

Contact Details

Contact Details

Related Glossary Terms

- chuck

chuck

Workholding device that affixes to a mill, lathe or drill-press spindle. It holds a tool or workpiece by one end, allowing it to be rotated. May also be fitted to the machine table to hold a workpiece. Two or more adjustable jaws actually hold the tool or part. May be actuated manually, pneumatically, hydraulically or electrically. See collet.

- collet

collet

Flexible-sided device that secures a tool or workpiece. Similar in function to a chuck, but can accommodate only a narrow size range. Typically provides greater gripping force and precision than a chuck. See chuck.

- fixture

fixture

Device, often made in-house, that holds a specific workpiece. See jig; modular fixturing.

- inner diameter ( ID)

inner diameter ( ID)

Dimension that defines the inside diameter of a cavity or hole. See OD, outer diameter.

- lathe

lathe

Turning machine capable of sawing, milling, grinding, gear-cutting, drilling, reaming, boring, threading, facing, chamfering, grooving, knurling, spinning, parting, necking, taper-cutting, and cam- and eccentric-cutting, as well as step- and straight-turning. Comes in a variety of forms, ranging from manual to semiautomatic to fully automatic, with major types being engine lathes, turning and contouring lathes, turret lathes and numerical-control lathes. The engine lathe consists of a headstock and spindle, tailstock, bed, carriage (complete with apron) and cross slides. Features include gear- (speed) and feed-selector levers, toolpost, compound rest, lead screw and reversing lead screw, threading dial and rapid-traverse lever. Special lathe types include through-the-spindle, camshaft and crankshaft, brake drum and rotor, spinning and gun-barrel machines. Toolroom and bench lathes are used for precision work; the former for tool-and-die work and similar tasks, the latter for small workpieces (instruments, watches), normally without a power feed. Models are typically designated according to their “swing,” or the largest-diameter workpiece that can be rotated; bed length, or the distance between centers; and horsepower generated. See turning machine.

- milling machine ( mill)

milling machine ( mill)

Runs endmills and arbor-mounted milling cutters. Features include a head with a spindle that drives the cutters; a column, knee and table that provide motion in the three Cartesian axes; and a base that supports the components and houses the cutting-fluid pump and reservoir. The work is mounted on the table and fed into the rotating cutter or endmill to accomplish the milling steps; vertical milling machines also feed endmills into the work by means of a spindle-mounted quill. Models range from small manual machines to big bed-type and duplex mills. All take one of three basic forms: vertical, horizontal or convertible horizontal/vertical. Vertical machines may be knee-type (the table is mounted on a knee that can be elevated) or bed-type (the table is securely supported and only moves horizontally). In general, horizontal machines are bigger and more powerful, while vertical machines are lighter but more versatile and easier to set up and operate.

- outer diameter ( OD)

outer diameter ( OD)

Dimension that defines the exterior diameter of a cylindrical or round part. See ID, inner diameter.

- turning

turning

Workpiece is held in a chuck, mounted on a face plate or secured between centers and rotated while a cutting tool, normally a single-point tool, is fed into it along its periphery or across its end or face. Takes the form of straight turning (cutting along the periphery of the workpiece); taper turning (creating a taper); step turning (turning different-size diameters on the same work); chamfering (beveling an edge or shoulder); facing (cutting on an end); turning threads (usually external but can be internal); roughing (high-volume metal removal); and finishing (final light cuts). Performed on lathes, turning centers, chucking machines, automatic screw machines and similar machines.

Rapid Options

Quick-change-jaw systems aren’t the only option when rapidly switching workholding for turning operations. Hainbuch America Corp., for example, offers a variety of quick-change workholding, including the Today, Tonight, Tomorrow (TTT) and the centroteX systems.

Tom Buraczewski, Midwest regional sales manager for Germantown, Wis.-based Hainbuch America, said the modular TTT system offers adapters for three workholding options: a collet for OD, an ID with an expanding mandrel and a 3-jaw chuck. While the collet chuck remains on the machine, an end user simply plugs one of the adapters into the chuck.

Holding on to an ID with an expanding mandrel is one workholding option for the TTT modular system. Image courtesy of Hainbuch America.

The centroteX quick-change interface allows workholding devices to be mounted on multiple milling and turning machines within a manufacturing plant. Image courtesy of Hainbuch America.

TTT allows a changeover to be made in about 2 minutes and is also suitable for milling applications, Buraczewski said. “The alternative is pulling the whole chuck off and installing a new one. Conservatively, that would take a half hour.”

He said one customer purchased a new Doosan machine and added the TTT system to machine parts from up to 2½"-dia. (63.5mm) bar stock and castings up to 6" (152.4mm) in diameter on the same spindle. The parts manufacturer is also looking at the modular system to hold parts on an ID with an expanding mandrel.

The centroteX system, Buraczewski added, goes a step further than the modular TTT system. “The centroteX does truly enable you to change to an entirely different workholding system,” he said, adding that the options include a collet chuck; a 3-, 4- or 6-jaw chuck; or even a special fixture for an odd-shaped casting for virtually any make or model of chuck. The workholders can be from other manufacturers besides Hainbuch.

“The system enables you to use the existing workholding already in your facility more effectively and more efficiently,” Buraczewski said.

According to the company, centroteX allows workholding devices to be mounted on multiple milling and turning machines within a manufacturing plant. This arrangement eases parts scheduling because a machine isn’t limited to just holding parts with one type of device, Buraczewski said.

“When a part comes up in the schedule,” he said, “you can run it on any machine because that machine has the flexibility to adapt to that part.”

In addition, the machine operator doesn’t require the extensive amount of training needed to conventionally change from one chuck to another, which might consume 45 minutes or more and require maintenance or skilled trade personnel, according to Buraczewski. Instead, an operator can be quickly and easily trained to make the 5-minute change using one Allen wrench. “We simplify the process,” he said.

As downtime reduction continues to remain a significant goal, manufacturers will continue to gravitate toward workholding systems that speed changeover. “Anything that we can do to shorten the downtime between parts is money in your pocket,” Buraczewski said.

—A. Richter

Contributors

Hainbuch America Corp.

(800) 281-5734

www.hainbuchamerica.com

Pratt Burnerd America

(800) 253-0820

www.prattburnerd.com

QCS Workholding LLC

(888) 869-2424

www.j-loc.com

SCHUNK Inc.

(919) 572-2705

www.us.schunk.com