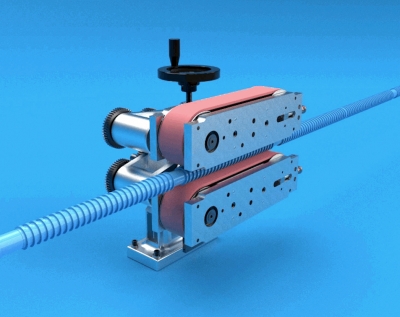

Versa Pullers presents caterpillar pullers, which provide uniform pressure over the entire traction length, thus exerting greater pulling force without product deformation. They are suitable for pliable materials like tubing, extruded profiles, foams, soft extruded materials like weather stripping. Versa series “C” pullers are available in non-motorized versions, which can be included in OEM designs, or in motorized versions that allow “out of the box” productivity. Belt configurations range from 2” (50 mm) width X 9” (230 mm) length to 4” (100 mm) width by 18” (460 mm) length.

A wide variety of belt materials are available including sponge, gum rubber, silicone, neoprene, urethane or nitrile some of which are FDA approved. Various durometer ratings are available to suit application requirements. Additional options include left-to-right configuration and OSHA guarding package.

All Versa pullers are equipped with a hand wheel or optional pneumatic operation of the belt booms along a constant centerline. The pneumatic option provides control of the pressure applied to the product being pulled and makes repeatable setup almost instantaneous. Additional options include left-to-right configuration and OSHA guarding package.

Motorized puller assemblies include all components for “out of the box” productivity for many downstream handling requirements. They are mounted on a 12” x 14” base plate for easy positioning of feed materials and include a choice of either AC or DC motor and drive, and a remote Operator Control Station (OCS), which can be mounted wherever desired. A wide variety of speed ranges are available. The OCS includes pushbuttons for start, stop and emergency stop, as well as a 10-turn potentiometer with turns counter for speed control. Digital speed indicator and 115-volt input are standard, with other voltages available as options.

Standard non-motorized “C” series puller assemblies are virtually identical to their motorized counterparts, except without the motor and drive. They provide excellent grip and feeding yet allow end users and OEM machine builders to design, configure and build machines to meet their specific requirements. With speeds from 0 to 450 feet per minute (fpm) and with a variety of belt materials available, they are ideal replacements for existing puller assemblies or as components for specialized equipment for unique applications.

Versa motorized pullers and caterpillar assemblies are ideal for many applications, including downstream handling of pipe, profiles, tubing, vinyl siding, wire and cable, steel materials, and pulling materials through braiding machines.

Contact Details

Related Glossary Terms

- feed

feed

Rate of change of position of the tool as a whole, relative to the workpiece while cutting.

- sponge

sponge

Form of metal characterized by a porous condition that is the result of the decomposition or reduction of a compound without fusion. The term is applied to forms of iron, titanium, zirconium, uranium, plutonium and the platinum group metals.