3D Printed PCD Monoblock Tool Bodies and Chip Deflectors

3D Printed PCD Monoblock Tool Bodies and Chip Deflectors

With 3D printing, there is about a 30% reduction in tool weight, yet it has the equivalent torsional stiffness of a steel ground body tool. Lightweighting can play a big role in large, heavy tools that take a toll on the machine spindle, helping to reduce preventative maintenance. These improvements can be significant when producing aerospace and automotive components, including electric vehicle parts, where existing spindle interfaces are not always ideal for some of the size/weight of tools.

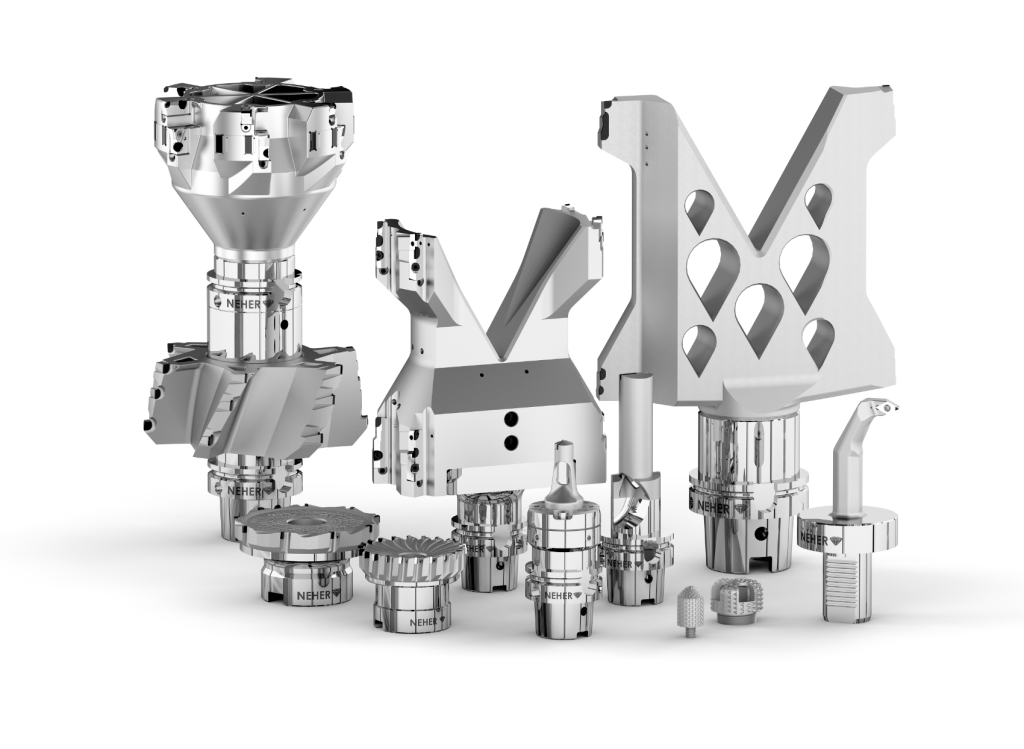

Star Cutter Company, in alliance with its strategic partner Neher Group, has announced the availability of 3D printed PCD monoblock tool bodies and chip deflectors where the 3D printed bodies are integrated with the holder interface to create a single robust tool. As compared to traditional manufacturing methods, additive manufacturing is more reliable in achieving designs with complex details and effective chip evacuation. This ability to optimize coolant hole and cooling channel locations can improve tool life by 30% or more and is well suited to the growing, and environmentally-friendly, MQL (minimum quantity lubrication) trend.

With 3D printing, there is about a 30% reduction in tool weight, yet it has the equivalent torsional stiffness of a steel ground body tool. Lightweighting can play a big role in large, heavy tools that take a toll on the machine spindle, helping to reduce preventative maintenance. These improvements can be significant when producing aerospace and automotive components, including electric vehicle parts, where existing spindle interfaces are not always ideal for some of the size/weight of tools.

Also available are 3D printed chip deflectors for applications that require total elimination of chips from the workpiece. These deflectors are mounted on the body of the tool so that when the tool is in the cut, the chip has no way to exit except through the flute channel.

The 3D printer technology is typically being applied to large reamers, interpolating and milling cutters. The company offers printing in a variety of materials including plastic, aluminum, titanium, steel and stainless. The Star Cutter engineering team works with all customers to provide the optimal tool design for each application.