Contact Details

Accurate targeting of coolant during machining provides maximum effectiveness in chip evacuation. However, precision and pressure are two equally important aspects of coolant. The higher the pressure, the more demanding applications can be machined with excellent results. Sandvik Coromant offers advanced nozzle technology and dedicated insert geometries for machining steel, stainless steel and HRSA materials.

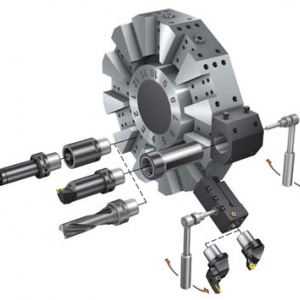

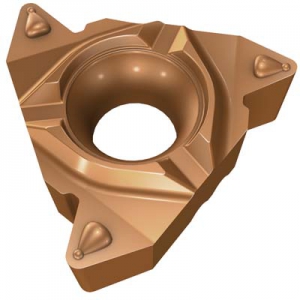

The company announced additions to the growing range of options to apply coolant in the machining process. The range of new insert geometries and customized tool holders feature fixed nozzles that guarantee a precise coolant jet flow accurately hitting the center of the cutting zone target.

The coolant flows from the pump to the tool through nozzles directed exactly at the cutting zone. This produces a wedge of coolant that efficiently removes the heat from the cutting zone and forms the chip. Improved chip control and longer tool life are just two of the benefits that contribute to secure and predictable machining, preventing unplanned machine stoppages.

Increased productivity can even be achieved in tricky applications, and in difficult to machine materials, regardless of the pressure you use.

When using low pressure of 7 to 10 bar (100 to 150 psi), the new Sandvik Coromant CoroTurn HP holders, with high precision nozzles, outperform regular tool holders that can have a tendency to flood coolant. This makes for improved chip control and better process security in steel and other common materials. Substantially higher cutting data can also be applied, as well.

For demanding materials, such as duplex stainless steel and HRSA material, higher coolant pressures are needed, such as 70 to 80 bar (1,000 to 1,200 psi). The unique CoroTurn HP nozzle technology in combination with the new-SMC, -MMC, -PMC insert geometries provides greater productivity.

Few machines provide solutions for pressures from 150 to 200 bar (2,200 to 2,900 psi), however Sandvik Coromant offers standard holders and inserts that allow for up to 275 bar (3900 psi) of coolant pressure. Coromant Capto clamping units for high-pressure coolant with 200 bar (2900 psi) coolant pressure capability provide enhanced performance, ensuring that machine utilization is optimized through reduced set-up and production time.

The Sandvik Coromant advanced cooling technology has been a solution primarily for customers using quick change with Coromant Capto, SL- and QS holding system. Now, the same premium technology can be applied with general shank tools, making it possible for everyone working with wet machining to utilize this highly productive coolant solution, even in small lathes.

Related Glossary Terms

- coolant

coolant

Fluid that reduces temperature buildup at the tool/workpiece interface during machining. Normally takes the form of a liquid such as soluble or chemical mixtures (semisynthetic, synthetic) but can be pressurized air or other gas. Because of water’s ability to absorb great quantities of heat, it is widely used as a coolant and vehicle for various cutting compounds, with the water-to-compound ratio varying with the machining task. See cutting fluid; semisynthetic cutting fluid; soluble-oil cutting fluid; synthetic cutting fluid.

- shank

shank

Main body of a tool; the portion of a drill or similar end-held tool that fits into a collet, chuck or similar mounting device.

PRODUCTS

PRODUCTS