Contact Details

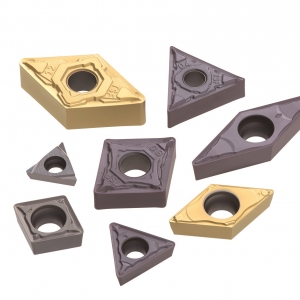

Tungaloy’s square shoulder milling cutter series has been expanded with AH3225 insert grade designed to provide an excellent balance of wear and fracture resistance for superior performance in steel machining.

AH3225 consists of the latest nano multi-layer coating technology with three major properties with excellent coating substrate adhesion for a high level of wear and fracture resistance. Integrating a dedicated carbide substrate with excellent thermal property provides the grade with increased thermal shock resistance and hardness reducing thermal crack generation on the cutting edge. This prevents unpredictable insert failure, significantly extending tool life and reliability for steel machining.

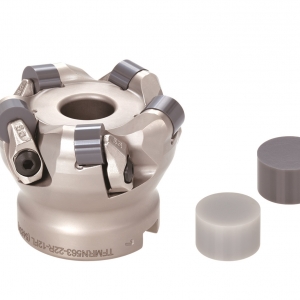

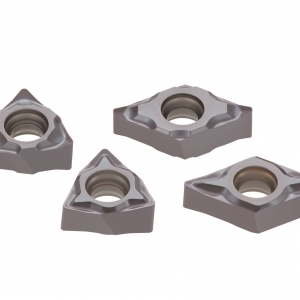

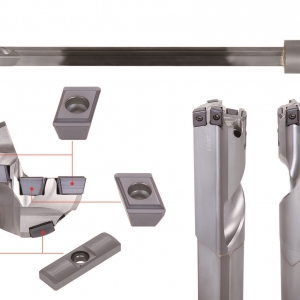

A total of 28 new inserts have been added in this expansion to three lines of Tungaloy’s finest square shoulder milling cutters: Tung-Tri boasts smooth cutting and exceptionally tool stability, TungForce-Rec features unique V bottom inserts for maximum productivity, and DoForce-Tri with its double-sided inserts with six cutting edges provides best production economy.

Related Glossary Terms

- gang cutting ( milling)

gang cutting ( milling)

Machining with several cutters mounted on a single arbor, generally for simultaneous cutting.

- hardness

hardness

Hardness is a measure of the resistance of a material to surface indentation or abrasion. There is no absolute scale for hardness. In order to express hardness quantitatively, each type of test has its own scale, which defines hardness. Indentation hardness obtained through static methods is measured by Brinell, Rockwell, Vickers and Knoop tests. Hardness without indentation is measured by a dynamic method, known as the Scleroscope test.

- milling

milling

Machining operation in which metal or other material is removed by applying power to a rotating cutter. In vertical milling, the cutting tool is mounted vertically on the spindle. In horizontal milling, the cutting tool is mounted horizontally, either directly on the spindle or on an arbor. Horizontal milling is further broken down into conventional milling, where the cutter rotates opposite the direction of feed, or “up” into the workpiece; and climb milling, where the cutter rotates in the direction of feed, or “down” into the workpiece. Milling operations include plane or surface milling, endmilling, facemilling, angle milling, form milling and profiling.

- milling cutter

milling cutter

Loosely, any milling tool. Horizontal cutters take the form of plain milling cutters, plain spiral-tooth cutters, helical cutters, side-milling cutters, staggered-tooth side-milling cutters, facemilling cutters, angular cutters, double-angle cutters, convex and concave form-milling cutters, straddle-sprocket cutters, spur-gear cutters, corner-rounding cutters and slitting saws. Vertical cutters use shank-mounted cutting tools, including endmills, T-slot cutters, Woodruff keyseat cutters and dovetail cutters; these may also be used on horizontal mills. See milling.

PRODUCTS

PRODUCTS