ChipMaster Chip Control Software

ChipMaster Chip Control Software

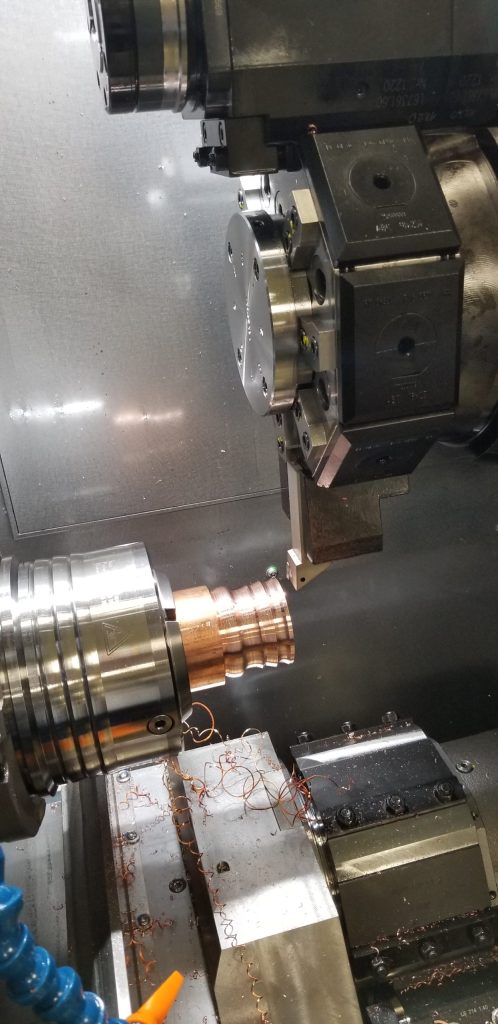

INDEX has announced the release of ChipMaster, a new chip-control software that effectively manages chip formation during turning, facing, contouring and cut off operations in all materials, including soft alloys such as copper and brass. Working within the programmed machining cycle, the software allows shops to avoid stringy chips on every cut, making chip disposal less troublesome and surface finishes consistently superior.

INDEX has announced the release of ChipMaster, a new chip-control software that effectively manages chip formation during turning, facing, contouring and cut off operations in all materials, including soft alloys such as copper and brass. Working within the programmed machining cycle, the software allows shops to avoid stringy chips on every cut, making chip disposal less troublesome and surface finishes consistently superior.

INDEX ChipMaster enables users to maximize machining speed and quality by optimizing chip formation with a variable feed on materials ranging from aluminum to titanium. Other benefits of the software include reduction in scrap, longer tool life, fewer unplanned interventions, and higher productivity and process reliability. In addition to process benefits, ChipMaster reduces the chances of operators injuring themselves on long, stringy chips and makes it easier to handle chips for recycling or disposal.

ChipMaster can be applied to any INDEX single and multiple-spindle machine with the latest Siemens control, and it is upgradable.

"ChipMaster represents our ongoing commitment to further enhancing the performance of our new machines, as well as those already in the field," said Tom Clark, president and CEO of INDEX in North America. "This is an extremely easy-to-implement and cost-effective solution to a longstanding issue for many manufacturers."