Combinator

Combinator

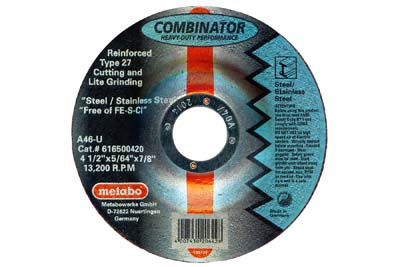

Metabo Corp. offers a combined cutting and grinding wheel.

Metabo Corp. offers a combined cutting and grinding wheel. The Combinator, designed for performance and safety, eliminates the need to change abrasive wheels during cutting and grinding applications. With the Combinator wheel, one grinder can be used for two applications.

The Combinator is ideal for cutting, deburring and light grinding. At 5/64" thick, it cuts quickly and with three full layers of fiberglass, safety is designed into the wheel for grinding applications.

The Combinator makes quick, clean and straight cuts in stainless steel, steel, alloy steels, hardened steels, pipe, tube and solids. This specially formulated wheel is contaminant-free, making these perfect for stainless steel grinding and cutting applications.

Available in 4-½", 5" and 6" type 27 versions, the Combinator employs an improved abrasive/resin formulation for fast cutting with increased wheel life, as well as strength and rigidity for grinding/metal-removal applications.