Contact Details

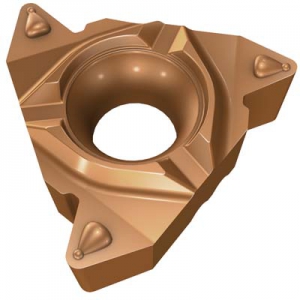

The main challenge in groove milling is often chip evacuation. Chip issues can harm production efficiency, lower component quality or cause tool breakage, especially when machining narrow and deep grooves. Dedicated for groove milling and parting off operations, CoroMill QD from Sandvik Coromant takes care of chip issues with optimized geometries and a unique internal coolant solution.

The insert geometry deforms chips to a more narrow shape than the groove, and then the chips are flushed out by coolant. This technology, combined with long and predictable tool life, makes CoroMill QD a reliable solution for secure and trouble-free production processes, according to the company.

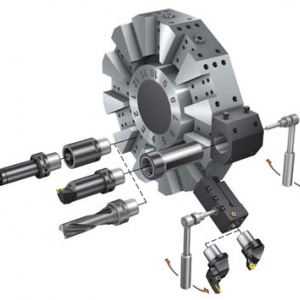

A range of new adapters complements the new cutters. These adapters enable use of CoroMill QD cutters regardless of whether the preferred machines are small- to medium-sized machining centers, large machining centers or multitask machines. Silent Tools adapters are available for long overhang machining.

The internal coolant is based on a four-channel delivery solution from the adapters to the cutter. By implementing this solution on the new adapters for CoroMill QD, coolant delivery into the groove is achieved.

Related Glossary Terms

- centers

centers

Cone-shaped pins that support a workpiece by one or two ends during machining. The centers fit into holes drilled in the workpiece ends. Centers that turn with the workpiece are called “live” centers; those that do not are called “dead” centers.

- coolant

coolant

Fluid that reduces temperature buildup at the tool/workpiece interface during machining. Normally takes the form of a liquid such as soluble or chemical mixtures (semisynthetic, synthetic) but can be pressurized air or other gas. Because of water’s ability to absorb great quantities of heat, it is widely used as a coolant and vehicle for various cutting compounds, with the water-to-compound ratio varying with the machining task. See cutting fluid; semisynthetic cutting fluid; soluble-oil cutting fluid; synthetic cutting fluid.

- gang cutting ( milling)

gang cutting ( milling)

Machining with several cutters mounted on a single arbor, generally for simultaneous cutting.

- milling

milling

Machining operation in which metal or other material is removed by applying power to a rotating cutter. In vertical milling, the cutting tool is mounted vertically on the spindle. In horizontal milling, the cutting tool is mounted horizontally, either directly on the spindle or on an arbor. Horizontal milling is further broken down into conventional milling, where the cutter rotates opposite the direction of feed, or “up” into the workpiece; and climb milling, where the cutter rotates in the direction of feed, or “down” into the workpiece. Milling operations include plane or surface milling, endmilling, facemilling, angle milling, form milling and profiling.

- parting

parting

When used in lathe or screw-machine operations, this process separates a completed part from chuck-held or collet-fed stock by means of a very narrow, flat-end cutting, or parting, tool.

PRODUCTS

PRODUCTS