Contact Details

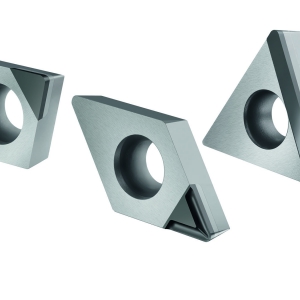

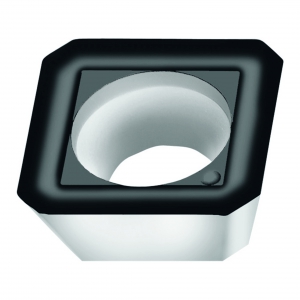

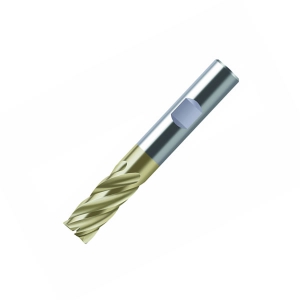

Walter has unveiled its new plug and play cylindrical modular interface for milling tools with diameters of 10-42 mm. Ideal as an interface for smaller tools, the new interface allows users maximum flexibility through exchanging modular milling tools, with payback in terms of time, cost, and reliability.

The new Walter cylindrical modular interface makes it easy to change existing copy, chamfer and shoulder milling tools, with no need to invest in new adaptors. It is easy to assemble and dismantle. Plus, the cylindrical centering reduces runout while providing a support face for good stability. Thanks to the stability and good concentricity of this tool interface, the result is a high level of process reliability and long tool life result.

Related Glossary Terms

- centering

centering

1. Process of locating the center of a workpiece to be mounted on centers. 2. Process of mounting the workpiece concentric to the machine spindle. See centers.

- gang cutting ( milling)

gang cutting ( milling)

Machining with several cutters mounted on a single arbor, generally for simultaneous cutting.

- milling

milling

Machining operation in which metal or other material is removed by applying power to a rotating cutter. In vertical milling, the cutting tool is mounted vertically on the spindle. In horizontal milling, the cutting tool is mounted horizontally, either directly on the spindle or on an arbor. Horizontal milling is further broken down into conventional milling, where the cutter rotates opposite the direction of feed, or “up” into the workpiece; and climb milling, where the cutter rotates in the direction of feed, or “down” into the workpiece. Milling operations include plane or surface milling, endmilling, facemilling, angle milling, form milling and profiling.

PRODUCTS

PRODUCTS