FloCut Multifunctional Groove Tooling System

FloCut Multifunctional Groove Tooling System

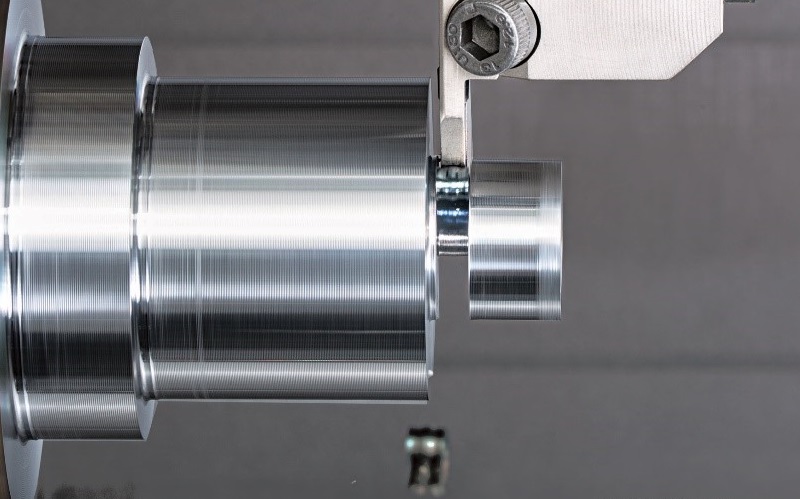

Tool-Flo presents FloCut, a multifunctional system for both external and internal applications. Its unique locking system yields increased stability, critical for side turning applications.

Tool-Flo presents FloCut, a multifunctional system for both external and internal applications. Its unique locking system yields increased stability, critical for side turning applications.

Additionally, the molded chip control geometries ensure optimal finishes on machined surfaces, while Tool-Flo's premium coatings ensure extended tool life. With a wide array of configurations for face grooving, deep grooving, side turning and parting applications, the FloCut system is also extremely versatile. Featuring holders that range from 0.500" to 1.250" (12 mm to 32 mm).