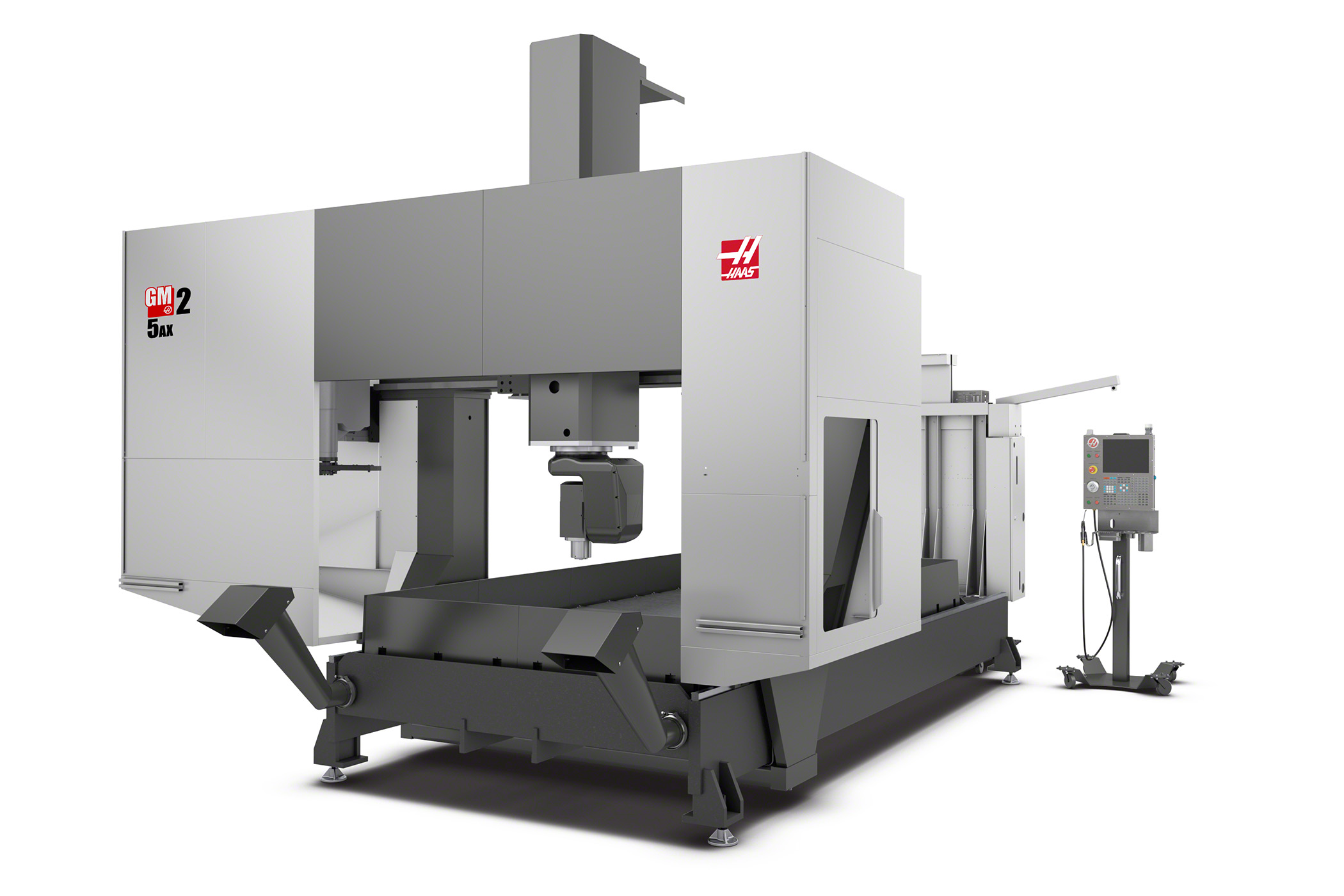

GM-2-5AX 5-Axis Gantry Mill

GM-2-5AX 5-Axis Gantry Mill

Many industries today, such as aerospace and automotive design, are turning to 5-axis machining to speed manufacturing processes and increase accuracy. The ability to machine complex shapes, undercuts, and difficult angles in a single setup reduces tooling costs and labor time, resulting in a better cost per part.

Many industries today, such as aerospace and automotive design, are turning to 5-axis machining to speed manufacturing processes and increase accuracy. The ability to machine complex shapes, undercuts, and difficult angles in a single setup reduces tooling costs and labor time, resulting in a better cost per part.

The Haas GM-2-5AX is a 5-axis gantry mill designed for complex, large-part machining, such as airframe components, layup molds and composite structures. The machine's dual-axis spindle head provides ±245 degrees of C-axis rotation and ±120 degrees of B-axis tilt for complex surfacing, or to access nearly any angle on a part. Travels are 145" x 87.5" x 39.4" (3683 x 2223 x 1000 mm), with 75" (1905 mm) between columns, and the machine comes standard with a 144" x 72" (3658 x 1829 mm) aluminum table. The GM-2-5AX's 20,000-rpm HSK 63F spindle features a 13.4 hp (10 kW) integral spindle/motor drive, and a 30+1 tool side-mount toolchanger is standard.

To simplify 5-axis setups, the GM-2-5AX comes equipped with Haas Automation's powerful Dynamic Work Offsets and Tool Center Point Control software. High-productivity options include the Haas Wireless Intuitive Probing System, a complete coolant system and dual chip augers.

For shops not requiring the flexibility of a dual-axis spindle head, Haas offers a 3-axis version of the GM-2. The 3-axis GM-2 provides the same X and Y axis travels as the 5AX, but with 22" (559 mm) of Z-axis travel, providing more rigidity for heavy machining. The GM-2 features a robust 40-taper inline direct-drive spindle that spins to 8100-rpm, and is powered by a 30 hp (22.4 kW) vector drive system. Optional 10,000-rpm and 15,000-rpm spindles are available for higher surface feeds and small tools. A 30+1 side-mount toolchanger also is standard.

The GM-2 is available with a wide selection options to boost productivity even further, such as high-pressure through-spindle coolant, dual-chip augers, the Haas Wireless Intuitive Probing System and a programmable coolant nozzle.