MR-4 Precision Micro Lathe

MR-4 Precision Micro Lathe

Microlution Inc., Chicago, recently introduced its MR-4 Precision Micro Lathe turning platform that reportedly offers positional accuracy of +/-0.00004" (1µm), maximum acceleration better than 2g, spindle speeds up to 15,000 rpm, tooling speeds up to 30,000 rpm and torque up to 6 Nm (S1), according to the company's website.

Microlution Inc., Chicago, recently introduced its MR-4 Precision Micro Lathe turning platform that reportedly offers positional accuracy of +/-0.00004" (1µm), maximum acceleration better than 2g, spindle speeds up to 15,000 rpm, tooling speeds up to 30,000 rpm and torque up to 6 Nm (S1), according to the company's website.

Microlution Inc., Chicago, recently introduced its MR-4 Precision Micro Lathe turning platform that reportedly offers positional accuracy of +/-0.00004" (1µm), maximum acceleration better than 2g, spindle speeds up to 15,000 rpm, tooling speeds up to 30,000 rpm and torque up to 6 Nm (S1), according to the company's website.

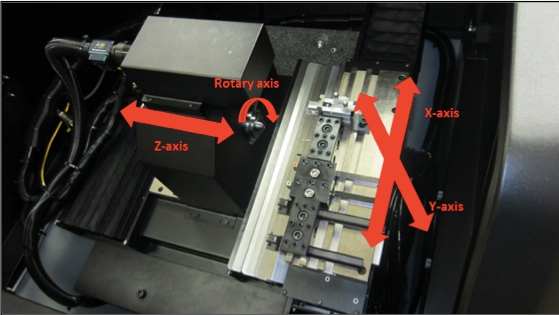

The precision-optimized micro lathe also is said to be capable of rotational accuracy up to 75 arc-sec (with an option for < 35 arc-sec). The working volume of the machine, which offers a 360° continuous rotary axis, is 11.81" in the X axis, 4.92" in the Y axis and 5.91" in the Z axis.

With a 40" x 60" footprint and a modular design, the MR-4 is said to be suitable for multiple configurations, and combines gang-style tooling and Swiss-style precision.