NamPower Abrasive Disc Brushes

NamPower Abrasive Disc Brushes

Brush Research Manufacturing (BRM), makers of the Flex-Hone tool, is showing manufacturers how to automate deburring and surface finishing with professional-grade NamPower abrasive disc brushes in a just-released YouTube video.

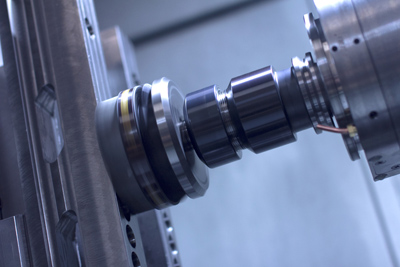

Brush Research Manufacturing (BRM), makers of the Flex-Hone tool, is showing manufacturers how to automate deburring and surface finishing with professional-grade NamPower abrasive disc brushes. In a just-released YouTube video, which can be viewed below, the company demonstrates how NamPower abrasive disc brushes provide maximum burr removal rates and an ideal surface finish at the same time.

BRM's new "How to Automate Deburring and Finishing" video features both Dot Style and Turbine Style brushes, and shows how NamPower technology uses a unique flow-through coolant system.