Contact Details

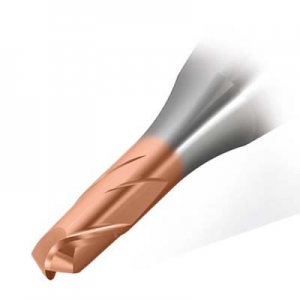

Walter USA LLC has introduced three new insert geometries that produce superior results in parting and grooving operations. Walter's CE4 geometry for medium to high feed rates features a tough cutting edge and good chip compression; the universal CF5 geometry for long-chipping materials and medium feed rates; and the CF6 geometry for low feed rates, non-ferrous metals, small diameters or thin-walled tubes.

All three geometries feature Walter's Tiger-tec Silver CVD coating technology which increases toughness and decreases machining time with optimized microstructure and resistance to thermal stress. They can be supplied in insert widths from 1.5 to 6.0mm and are currently available in the WSM33S and WSM43S cutting materials. This combination of factors enables the new geometries to produce superior chip formation and burr resistance, improved process reliability and cycle times, and an overall boost in price/performance ratio.

Related Glossary Terms

- burr

burr

Stringy portions of material formed on workpiece edges during machining. Often sharp. Can be removed with hand files, abrasive wheels or belts, wire wheels, abrasive-fiber brushes, waterjet equipment or other methods.

- chemical vapor deposition ( CVD)

chemical vapor deposition ( CVD)

High-temperature (1,000° C or higher), atmosphere-controlled process in which a chemical reaction is induced for the purpose of depositing a coating 2µm to 12µm thick on a tool’s surface. See coated tools; PVD, physical vapor deposition.

- feed

feed

Rate of change of position of the tool as a whole, relative to the workpiece while cutting.

- grooving

grooving

Machining grooves and shallow channels. Example: grooving ball-bearing raceways. Typically performed by tools that are capable of light cuts at high feed rates. Imparts high-quality finish.

- microstructure

microstructure

Structure of a metal as revealed by microscopic examination of the etched surface of a polished specimen.

- parting

parting

When used in lathe or screw-machine operations, this process separates a completed part from chuck-held or collet-fed stock by means of a very narrow, flat-end cutting, or parting, tool.

PRODUCTS

PRODUCTS