Vertical Turning Center Grinding Attachment

Vertical Turning Center Grinding Attachment

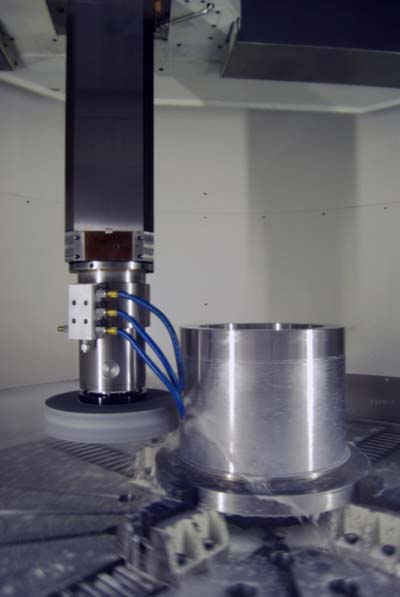

A new automatically changed grinding attachment adds surface finishing to the one-stop processing capabilities of MAG's vertical turning centers, allowing finishing of ID, OD and plane surfaces on parts up to 4700mm (185 inches) diameter.

A new automatically changed grinding attachment adds surface finishing to the one-stop processing capabilities of MAG's vertical turning centers, allowing finishing of ID, OD and plane surfaces on parts up to 4700mm (185 inches) diameter. The system is ideal for large bearings and gearboxes used in machinery for the mining, construction, marine and energy industries. VTC's equipped with the new 22/33 kW (29.5/44 hp) grinding attachment can produce better than 10 micro inch finishes and roundness of less than 60 micro inch, with diameter size control of 0.025mm (0.001 inches).

The grinding attachment can utilize wheel sizes up to 400mm (15.75 inches) and produces 400 Nm (295 ft lb) torque and a maximum speed of 3000 rpm. Equipped for grinding work, VTC's are enhanced with a modified coolant and filtration system, hand-held wash wand, stainless steel bowl enclosure with extra side flush, covers over the column ways, and a heavy duty chip conveyor to handle grinding swarf. Full X-axis travel on MAG VTC's provides room for a highly rigid dressing tool outside the work zone, allowing the machine to accept its maximum part size without restriction.

Normally stored in an off-line tool drawer, the grinding attachment joins live spindles, right-angle heads, horizontal adapters and other attachments that can be changed automatically on the VTC's for maximum machine uptime and single-setup part completion. One of the most versatile turning systems for large parts, MAG's VTC's in table size 1000mm to 4500mm (39.4 to 177 inches) can already perform standard and hard turning, as well as live-spindle machining, contouring and part probing operations on multiple sides and the full diameter of a part. Ideal for grinding applications, these machines are FEA-designed for maximum strength-to-weight ratio, stiffness and rigidity, with heavily ribbed cast iron or robust steel weldments used for major components, such as base, column and cross slide, depending on the machine size.

The adjustable cross slide, with MAG's unique leveling technique and patented rail clamping system, allows ram extension to be minimized during grinding for maximum system stiffness. A Wedge Lock tooling system with hydraulic clamping force of 150,000 N (33,000 lb) allows use of tools up to 700mm (27.5 inches) long. The 250mm-square (10 inches) hydrostatic ram resists torsion and vibration to produce superior surface finishes, and allows downward feed thrust up to 34,000 N (7,600 lb). Cross rail leveling with dual linear scales ensures parallelism between table and rail, with leveling accuracy of 10µm (0.0004 inches). Preloaded roller guideways enhance system stiffness and reduce friction for excellent contouring accuracy.

Tables are extensively supported with a combination of tapered roller and flat thrust bearings to handle constant use at maximum load ratings. The table design resists tipping with unbalanced loads, and superior accuracy is ensured with factory-specified maximum 0.005mm (0.0002 inches) table runout. Table drives are rated 84 kW (112 hp) to 108 kW (145 hp), and capable of producing maximum torque of 17,113 Nm (12,623 ft lb) to 111,116 Nm (81,955 ft lb). Full contouring with the table C-axis enables drilling, tapping or mill turning of features anywhere on the workpiece with contouring/positioning by 360,000-position table.

A standard 26-position tool changer accommodates six Wedge Lock and 20 modular tools. Various options for the VTC line include expanded tool capacity, part and tool probing systems, pallet changer and fourth axis. Fanuc 310i or Siemens 480D controls are standard.