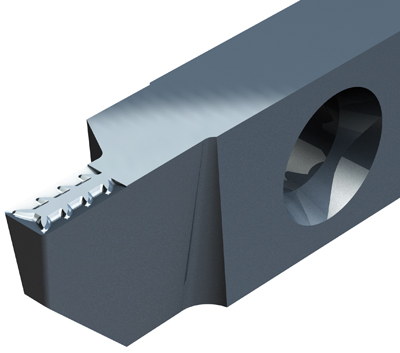

ZX10 Inserts

ZX10 Inserts

FLP Tooling distributes the newly launched Applitec ZX10 and ZXT10 700 Series inserts, which reportedly provide greatly increased chip control with specialized chip breakers.

FLP Tooling distributes the newly launched Applitec ZX10 and ZXT10 700 Series inserts, which reportedly provide greatly increased chip control with specialized chip breakers. These chip breakers pull the chips away from the material and promote faster chip break-away.

Both the ZX10 and ZXT10 are best for machining steel, stainless steel and titanium in grooving/turning and back turning operations Multiple thickness and radius options are available in TiAlN coating (TiN available upon request).