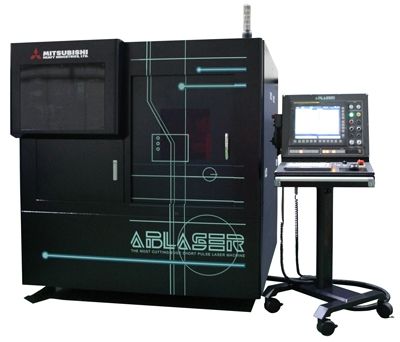

Mitsubishi Heavy Industries Ltd. (MHI) has developed a laser micromachining system, dubbed the "ABLASER," as its first product in the laser processing machine business. The adoption of a proprietary high-precision optical system and other innovations enable high-speed, high-precision drilling and other machining applications requiring superior accuracy. MHI will commence sales activities within the current fiscal term ending next March, and looks to attract broad-based demand for the ABLASER by proposing solutions for a wide array of diverse machining situations.

The ABLASER adopts a high-quality laser source that continuously irradiates an ultra-short pulse laser with a pulse duration below 10 picoseconds (pico = 10-12). It features a laser head that employs a high-precision lens, prism and other components to refract and rotate the laser beam at will. Thermal affection on the processing surface is reduced by ablating the machining area with high peak power. When used for drilling, the ABLASER achieves dimensional accuracy exceeding that of electric discharge machining, enabling fast machining of difficult jobs such as negative tapered holes (in which the bore widens conically as the hole deepens), oval-shaped holes.

Granite is applied to the ABLASER's major structural components to maintain outstanding anti-vibration effect and minimal thermal displacement. A precision scale is also installed in the positioning component. Together these features achieve high quality surpassing that of laser machines available until now. In addition, the adoption of 5-axis control as found in advanced machine tools facilitates machining onto curved surface complex shapes.