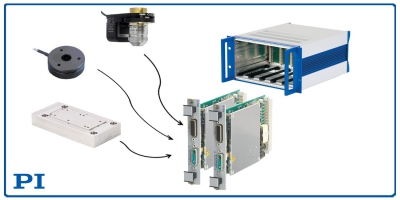

PI (Physik Instrumente) L.P has expanded its E-709 family of low-cost digital piezo nanopositioning controllers with a new plug-in module for the C-885 PIMotionMaster modular controller system.

The PIMotionMaster system allows the combination of different drive technologies, controlled through one interface via one software package. For example, stepper motor stages, closed-loop servo motor positioners, and fast piezo-driven nano-focus devices can now be operated from one controller. Up to 20 control cards can be plugged into one 19” rack.

The latest piezo control module, the E-709.1CC885, supports functions including wave generator, data recorder, auto zero and I/O triggers. With a sensor update rate of 10kHz, two notch filters and linearization algorithms based on fifth-order polynomials it provides exceptionally accurate motion with sub-nanometer precision. The E-709 card combines a power amplifier (-30 to 130V output), signal conditioning circuitry for capacitance sensors and a digital servo. Piezo controllers with digital servo offer the advantage of higher linearity, and easy access to advanced features in comparison to conventional analog piezo controllers. A comprehensive software package is included: drivers for LabVIEW, dynamic libraries for Windows and Linux, MATLAB, MetaMorph, µManager, Andor iQ. Interfaces include USB, SPI, RS-232, and analog.

After the modules are installed in the rack, individual axis configuration and movement is easily set-up using the included PIMikroMove software, a comprehensive Windows GUI that does not require programming knowledge for commissioning or direct operation.

Modules are currently available for PI translation/rotation stages equipped with:

- DC motors

- 3-phase motors

- Stepper motors

- Piezo flexure positioners

- Piezo ultrasonic motors

- PiezoWalk nanopositioning motors

- Piezo inertia motors

Fields of applications include precision motion control in automation, nanopositioning, photonics, semiconductor testing, laser machining.

Contact Details

Related Glossary Terms

- laser machining

laser machining

Intensified, pulsed beams of light generated by lasers—typically carbon dioxide or neodium-doped yttrium aluminum garnet (Nd:YAG)—that drill, weld, engrave, mark, slit and caseharden. Usually under CNC, often at both high cutting rates (100 linear in./sec.) and high power (5kW or more). Lasers also are used in conjunction with in-process quality-control monitoring systems allowing measuring accuracies of 0.00001".