Contact Details

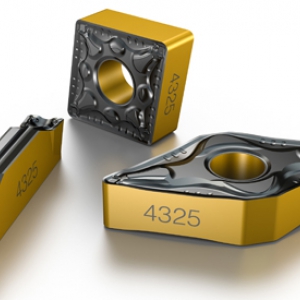

The CoroDrill 870 from Sandvik Coromant Co. is part of a new generation of exchangeable-tip drills and was recently launched for steel and cast iron drilling.

CoroDrill 870 can be tailored to optimize applications through diameter range, steps and length possibilities. Holes can be made more efficiently and closer to the specifications required, leaving them better suited to subsequent operations. A highly secure interface between drill body and tip ensures reliability and precision, while the quick and easy tip change procedure maximizes active machining time.

The new cutting edge geometries and grades provide a safe cutting process, allowing for increased penetration rates while maintaining chip control and increasing tool life. Grade GC2234 includes a fine-grained high chromium substrate and a new PVD coating with optimized composition for ISO M drilling (stainless). The thin AlTiN PVD coating includes enhanced adhesion steps resulting in longer tool life and increased chipping resistance.

The drill is available in diameter range 10.00 to 26.65mm (0.394 to 1.049 inch) and lengths up to 8 times the drill diameter as standard. Each drill body has a unique interface size with matching tips to achieve hole tolerances of H9 to H10.

Related Glossary Terms

- physical vapor deposition ( PVD)

physical vapor deposition ( PVD)

Tool-coating process performed at low temperature (500° C), compared to chemical vapor deposition (1,000° C). Employs electric field to generate necessary heat for depositing coating on a tool’s surface. See CVD, chemical vapor deposition.

PRODUCTS

PRODUCTS