Contact Details

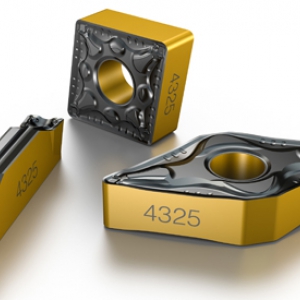

Cutting tool and tooling system specialist Sandvik Coromant is introducing a completely new range of high-end versatile solid end mills. The CoroMill® Dura will replace the existing versatile CoroMill® Plura end mills. The concept is developed for roughing to finishing with different engagements in all applications and materials.

What makes the CoroMill® Dura stand out compared to the former versatile concept and competitor end mills is its WhisperKut™ technology. Dr. Markus Groppe, Global Product Application Manager at Sandvik Coromant, explains the unequal helix concept: “Each flute is oriented at a different helix angle, and every level of the cutting edge is unequally spaced from the others. This way, you can achieve very good stability and efficient machining without vibration.”

Another noticeable feature is how easy it is to choose the correct tool within the comprehensive range of solid end mills presented in the offering. “We have put a lot of effort into tool selection. Finding the right tool within the CoroMill® Dura assortment should never be a struggle,” continues Groppe.

First choice is the four-flute plug-and-play solution, which works for a wide range of applications. Additional tool variants are available for more specific operations, such as key slots, dynamic milling, semi-finishing and finishing. Further assistance comes from the CoroPlus® Tool Guide for CoroMill® Dura online tool selector, which supports slotting, side milling, pocketing and helical interpolation applications to make tool selection simpler.

The CoroMill® Dura is available from two to seven flutes with 1-4×D cutting length, with and without a chip divider. The end mills can be reconditioned up to three times to original specifications.

Related Glossary Terms

- flutes

flutes

Grooves and spaces in the body of a tool that permit chip removal from, and cutting-fluid application to, the point of cut.

- gang cutting ( milling)

gang cutting ( milling)

Machining with several cutters mounted on a single arbor, generally for simultaneous cutting.

- helix angle

helix angle

Angle that the tool’s leading edge makes with the plane of its centerline.

- interpolation

interpolation

Process of generating a sufficient number of positioning commands for the servomotors driving the machine tool so the path of the tool closely approximates the ideal path. See CNC, computer numerical control; NC, numerical control.

- milling

milling

Machining operation in which metal or other material is removed by applying power to a rotating cutter. In vertical milling, the cutting tool is mounted vertically on the spindle. In horizontal milling, the cutting tool is mounted horizontally, either directly on the spindle or on an arbor. Horizontal milling is further broken down into conventional milling, where the cutter rotates opposite the direction of feed, or “up” into the workpiece; and climb milling, where the cutter rotates in the direction of feed, or “down” into the workpiece. Milling operations include plane or surface milling, endmilling, facemilling, angle milling, form milling and profiling.

- slotting

slotting

Machining, normally milling, that creates slots, grooves and similar recesses in workpieces, including T-slots and dovetails.

PRODUCTS

PRODUCTS