LICS-300H Laser Calibration System

LICS-300H Laser Calibration System

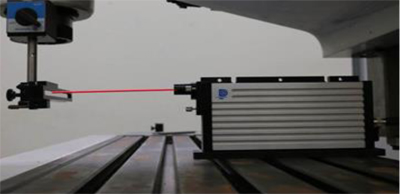

Optodyne Inc. has announced a new high performance and compact LICS-300H for the measurement of 3D volumetric positioning errors, including the 3 displacement errors, 6 straightness errors and 3 squareness errors.

Optodyne Inc. has announced a new high performance and compact LICS-300H for the measurement of 3D volumetric positioning errors, including the 3 displacement errors, 6 straightness errors and 3 squareness errors.

The LICS-300H Laser Calibration System features a two main components system. The barometric pressure, air temperature and material thermal expansion can be automatically corrected. The straightness is measured by a quad-detector target. The output is the vertical and horizontal straightness. The squareness is determined by an optical square, which bends the laser beam exactly 90 degrees. The 2D time base is used to measure the dynamic contours, velocity, acceleration and mechanical vibrations.

It is a turn-key laser measurement system using Windows OS and USB interface. The software capable of automatic data collection, data analysis based on ISO 230 and ASME B5 standards and generates pitch error compensation files for most controllers. The laser stability is 0.05 ppm. The measurement accuracy is 0.5 ppm and traceable to NIST. The measurement range is 400" or 10 meters.