Inserts

Guhring System 222 Part-off Tooling

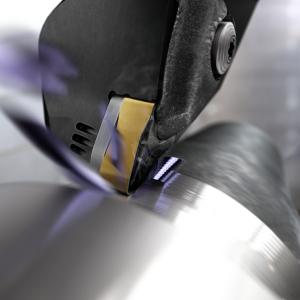

Post-processing operations can be eliminated with System 222. Guhring’s cutting geometries for steel, stainless steel and cast iron are sintered right into the inserts. The standard offering includes 2mm and 3mm wide inserts in left, right and neutral versions; a single-sided insert version allows for even deeper reach. Blade-style and square shank holders are available with and without internal coolant.

IMTS 2022 Booth Visit with Allied Machine and Engineering

John Weniger, the product manager for Allied Machine and Engineering’s T-A Pro line, provides a brief overview and demonstration of the T-A Pro M geometry insert.

Click here to visit Allied Machine and Engineering's website.

Risk Detected and Averted: Cutting Insert Warns Before Breakage

Selecting the right insert to machine the wide variety of steel materials can be challenging. To make machining steel easier to navigate, CERATIZIT has rethought everything about its new ISO-P turning insert. From the substrate to the geometries, right through to the Dragonskin coating, CERATIZIT inserts ensure that you are prepared for every steel turning challenge.